- Joined

- Oct 11, 2016

- Messages

- 3,855

first: Congrats! I LOVE LeBlond lathes! (I don't have one)

In order to get going safely and to preserve the machine, you need to obtain some kind of way cover, as above, but

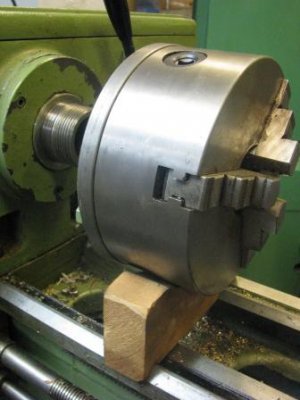

the most important project I did for my lathe is: (drum roll please) a block or plate for your lathe chuck so you can position your chuck to put it on/take it off without the possibility of a 'ding' on the ways.

Here's mine:

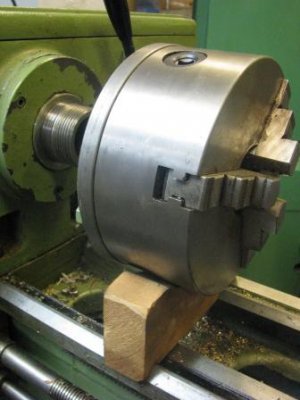

Some people just use a hunk of plywood:

I know, you are asking for is a project - in metal- to turn on your lathe!

Problem is, I turn on my lathe 20 times a week for little 5 minute jobs. I never do 'lathe projects' But I couldn't live without it!

Do you have a hard or micrometer carriage stop? - very handy!

In order to get going safely and to preserve the machine, you need to obtain some kind of way cover, as above, but

the most important project I did for my lathe is: (drum roll please) a block or plate for your lathe chuck so you can position your chuck to put it on/take it off without the possibility of a 'ding' on the ways.

Here's mine:

Some people just use a hunk of plywood:

I know, you are asking for is a project - in metal- to turn on your lathe!

Problem is, I turn on my lathe 20 times a week for little 5 minute jobs. I never do 'lathe projects' But I couldn't live without it!

Do you have a hard or micrometer carriage stop? - very handy!