-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just started reconditioning a pretty decent 101.07301 have some questions for the experienced!

- Thread starter makeparts

- Start date

I took a closer look at the belts - I don't think they are original, but I don't really know. Brought them to an auto-parts store, and put them on a belt measuring tool.

What I assume is the motor-countershaft (smaller) belt is a Gates Trueflex l230 (there is some wear, but I can see the word Gates, most of the word Trueflex, top of the L, and most of the 230). The belt measuring tool says it is a ~222 belt. Does "11" imply 3/8". I don't know much about them, and the kids at the autoparts store didn't either.

The larger belt (countershaft-headstock?) is also a Gates Trueflex L310. This belt doesn't have painted lettering - they are embossed/stamped into the top of the belt. The measuring tool shows this belt to be a ~297 belt.

do belts shrink over time? does the measuring tool have the capacity to measure l belts, or is this causing erroneous readings?

Taking a look, and chatting with the autoparts guys, we <think> these belts could be used to get it moving again. The smaller belt is almost round, and not much wear...the longer belt does have a smaller bend in memory, but not as bad as other new belts I have seen.

What I assume is the motor-countershaft (smaller) belt is a Gates Trueflex l230 (there is some wear, but I can see the word Gates, most of the word Trueflex, top of the L, and most of the 230). The belt measuring tool says it is a ~222 belt. Does "11" imply 3/8". I don't know much about them, and the kids at the autoparts store didn't either.

The larger belt (countershaft-headstock?) is also a Gates Trueflex L310. This belt doesn't have painted lettering - they are embossed/stamped into the top of the belt. The measuring tool shows this belt to be a ~297 belt.

do belts shrink over time? does the measuring tool have the capacity to measure l belts, or is this causing erroneous readings?

Taking a look, and chatting with the autoparts guys, we <think> these belts could be used to get it moving again. The smaller belt is almost round, and not much wear...the longer belt does have a smaller bend in memory, but not as bad as other new belts I have seen.

Attachments

ah yes that is possible. don't articulate, but that seems like a good bet.They both appear to be indicator holders, the brass one possibly home made.

What I assume is the motor-countershaft (smaller) belt is a Gates Trueflex l230 (there is some wear, but I can see the word Gates, most of the word Trueflex, top of the L, and most of the 230). The belt measuring tool says it is a ~222 belt. Does "11" imply 3/8". I don't know much about them, and the kids at the autoparts store didn't either.

The larger belt (countershaft-headstock?) is also a Gates Trueflex L310. This belt doesn't have painted lettering - they are embossed/stamped into the top of the belt. The measuring tool shows this belt to be a ~297 belt.

The belt appears in the 13/15 range on the tool so that is where you should read the length, at the 13/15 line on the gauge window. You also need to put a lot of tension on the belt, particularly with older stiffer belt

With a bench mounted motor and bench mounted counter shaft belt length is not critical as you can position each to adjust.

- Joined

- Dec 25, 2011

- Messages

- 10,507

I don't know what the brass bracket is but it isn't a part of the basic lathe. The steel bar with rod sticking out of one end could just be a straight edge, with the rod for a handle. Although what you would use it for with the lathe I don't know.

If the paper washers fit the M6-250 back gear shaft, they are probably the M6-255 Washer. Which serve as shims. They would go between the collars and the back gear assembly. The 1950 618 parts list shows two of them, one at either end of the back gear and calls them Fiber Washer. The 1945 version only shows one and calls it a Washer. If you haven't already done it, download the 1945 and the 1950 618 manuals from Downloads. The 1945 version includes the lathe and countershaft mounting drawing. And shows the motor mounted up next to the countershaft bracket with the pulleys on the left end. However, although I cannot find it in your photo, your countershaft bracket is probably much shorter than the Type 3 shown in those two parts manuals. So after bolting down the lathe bed, temporarily position the countershaft where the 618 and 101.21400 drawings call for and make sure that the belts all fit before drilling the holes.

If the paper washers fit the M6-250 back gear shaft, they are probably the M6-255 Washer. Which serve as shims. They would go between the collars and the back gear assembly. The 1950 618 parts list shows two of them, one at either end of the back gear and calls them Fiber Washer. The 1945 version only shows one and calls it a Washer. If you haven't already done it, download the 1945 and the 1950 618 manuals from Downloads. The 1945 version includes the lathe and countershaft mounting drawing. And shows the motor mounted up next to the countershaft bracket with the pulleys on the left end. However, although I cannot find it in your photo, your countershaft bracket is probably much shorter than the Type 3 shown in those two parts manuals. So after bolting down the lathe bed, temporarily position the countershaft where the 618 and 101.21400 drawings call for and make sure that the belts all fit before drilling the holes.

I don't know what the brass bracket is but it isn't a part of the basic lathe. The steel bar with rod sticking out of one end could just be a straight edge, with the rod for a handle. Although what you would use it for with the lathe I don't know.

It's an indicator holder for a lantern/rocker style tool post. This is the Starrett version:

there is 1 item I cannot identify, and a few parts I don't think are part of the lathe, but not being a real machinist, I have a long list of unknown unknowns :|

the "few parts" are a brass 90deg. fitting bracket, with 2 brass wing nuts, and another larger allow wing nut with an attached rubber? washer on the mating surface.

Both of those parts look like hardware for holding test or dial indicators. The steel piece looks like it mounts in the lantern tool post holder. The round rod is to attach the indicator to. The brass piece with the wing nuts looks like it slides over the round rod on the other tool post mounted piece to attach the indicator at a 90 degree angle. Neither is technically part of the lathe, but you'll use both regularly.

paulh

ah I see thanks RobertThe belt appears in the 13/15 range on the tool so that is where you should read the length, at the 13/15 line on the gauge window. You also need to put a lot of tension on the belt, particularly with older stiffer belt

With a bench mounted motor and bench mounted counter shaft belt length is not critical as you can position each to adjust.

I have the manuals with the motor locating holes, which I'll use as a reference/alignment, but yeah, I'll be able to fit them to the belts

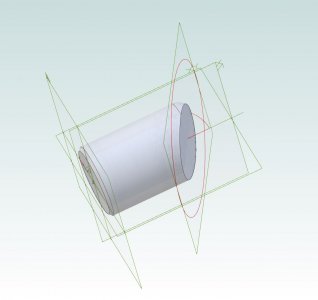

I had a few minutes this am, so I drew up a 3D model of the M6-309 pin. Its in a parametric modeling tool, so when I get a chance to get the best measurements I can, I'll update dimensions and push 2d drawings (and the 3D model file, if anyone is interested).