- Joined

- Dec 25, 2011

- Messages

- 10,511

OK. Thanks. Or maybe two photos, one slightly to the right and one slightly to the left of center.

The back gear assembly as far as I can tell, and most of the rest of the lathe outside of the headstock and the countershaft bracket is exactly the same as the 618. Exceptions that I know of so far are the countershaft bracket, for some unknown reason the lead screw, and a few other parts around and about. If you look in downloads, and get the 101.07301 parts manual and the 1950 dated 618 manual and compare them, you will see what I mean. If the part number on the Craftsman list begins with an "L" and a digit, it is somehow different. If it begins with M6, it is the same.

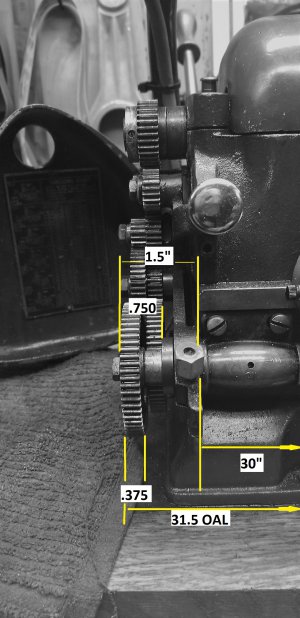

Which reminds me, if you or anyone else has occasion to have the lead screw off of either a 618 or a 101.07301, measure the LOA and the length from the left end to the left face of the collar and report it here.

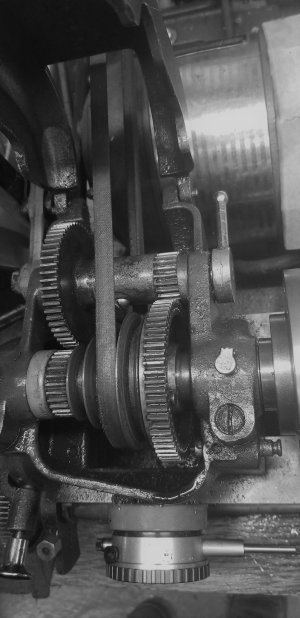

Back to the back gears, it would appear that the correct location for the two M6-255 Fiber Washers is on on each end of the gear, between the collar and the gear.

The back gear assembly as far as I can tell, and most of the rest of the lathe outside of the headstock and the countershaft bracket is exactly the same as the 618. Exceptions that I know of so far are the countershaft bracket, for some unknown reason the lead screw, and a few other parts around and about. If you look in downloads, and get the 101.07301 parts manual and the 1950 dated 618 manual and compare them, you will see what I mean. If the part number on the Craftsman list begins with an "L" and a digit, it is somehow different. If it begins with M6, it is the same.

Which reminds me, if you or anyone else has occasion to have the lead screw off of either a 618 or a 101.07301, measure the LOA and the length from the left end to the left face of the collar and report it here.

Back to the back gears, it would appear that the correct location for the two M6-255 Fiber Washers is on on each end of the gear, between the collar and the gear.

Last edited: