- Joined

- Dec 3, 2013

- Messages

- 1,844

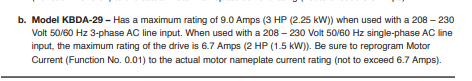

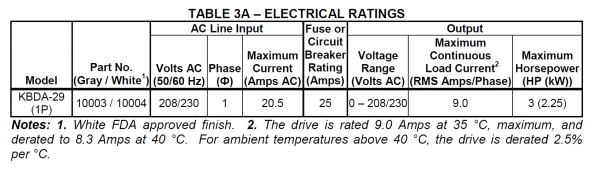

I powered up the KBDA-29(1p) and anything over 15Hz the motor stumbles and the Overload LED blinks. I have set the motor Amps to the name plate of 7.6. AC power is good so not sure where to go from here. Maybe something in the Operating Parameters?

Photo of the motor nameplate and video of what is happening.

https://drive.google.com/file/d/0Bxq8HLuwIa5jNTdGbFlCNEljdktJQ210aVlsaFB1ay1uZFJB/view?usp=sharing

Photo of the motor nameplate and video of what is happening.

https://drive.google.com/file/d/0Bxq8HLuwIa5jNTdGbFlCNEljdktJQ210aVlsaFB1ay1uZFJB/view?usp=sharing