- Joined

- Nov 25, 2015

- Messages

- 335

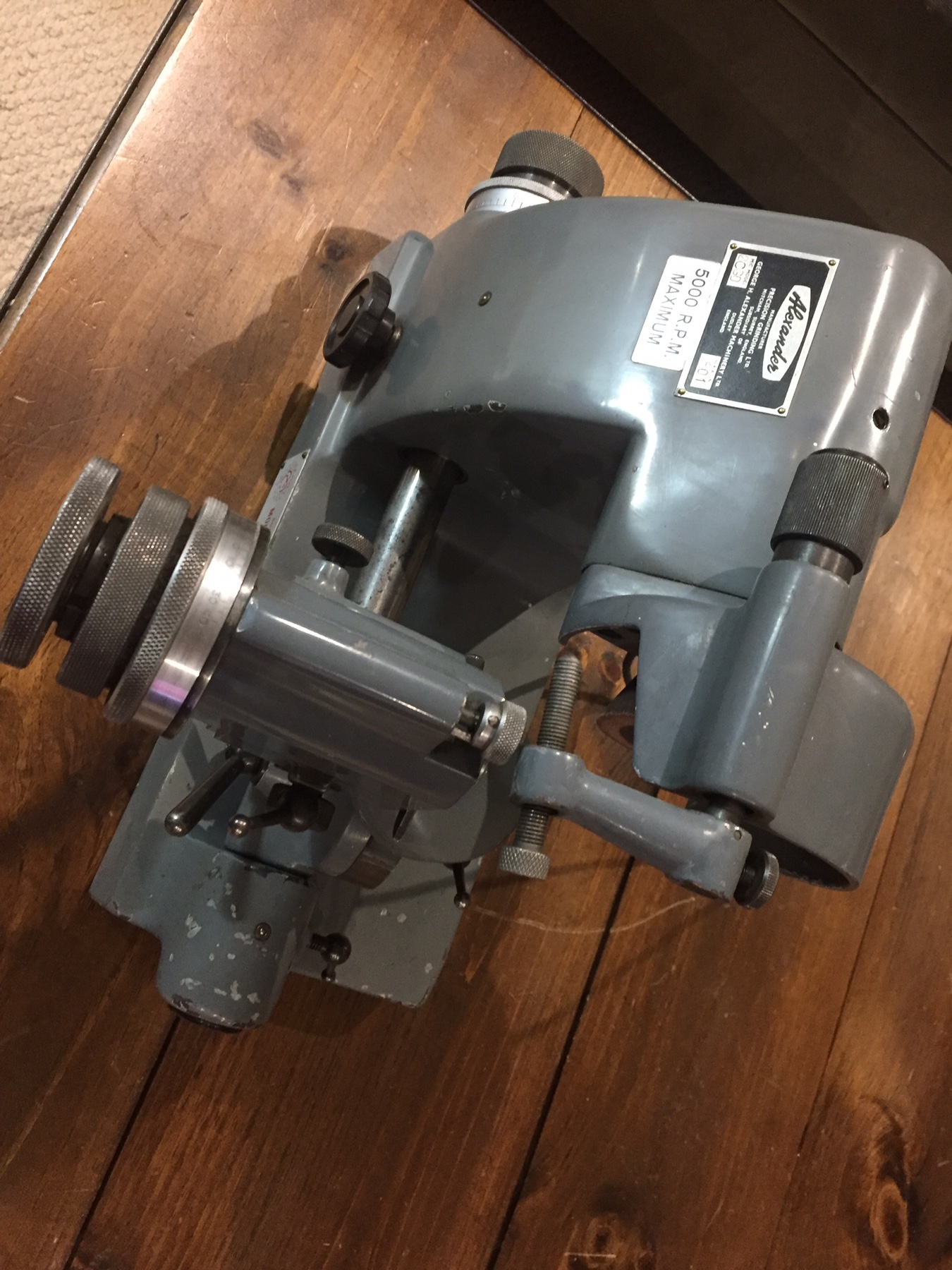

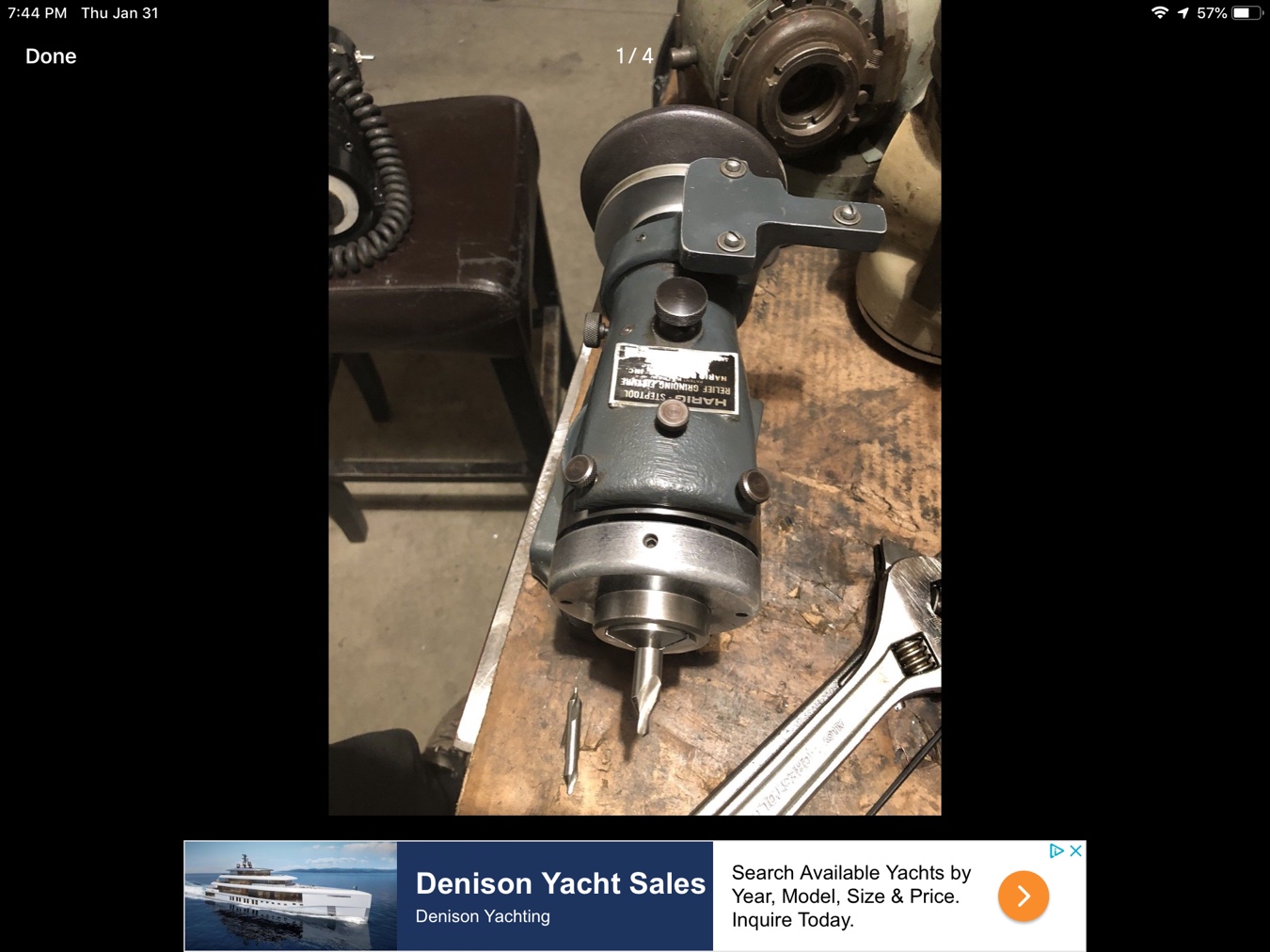

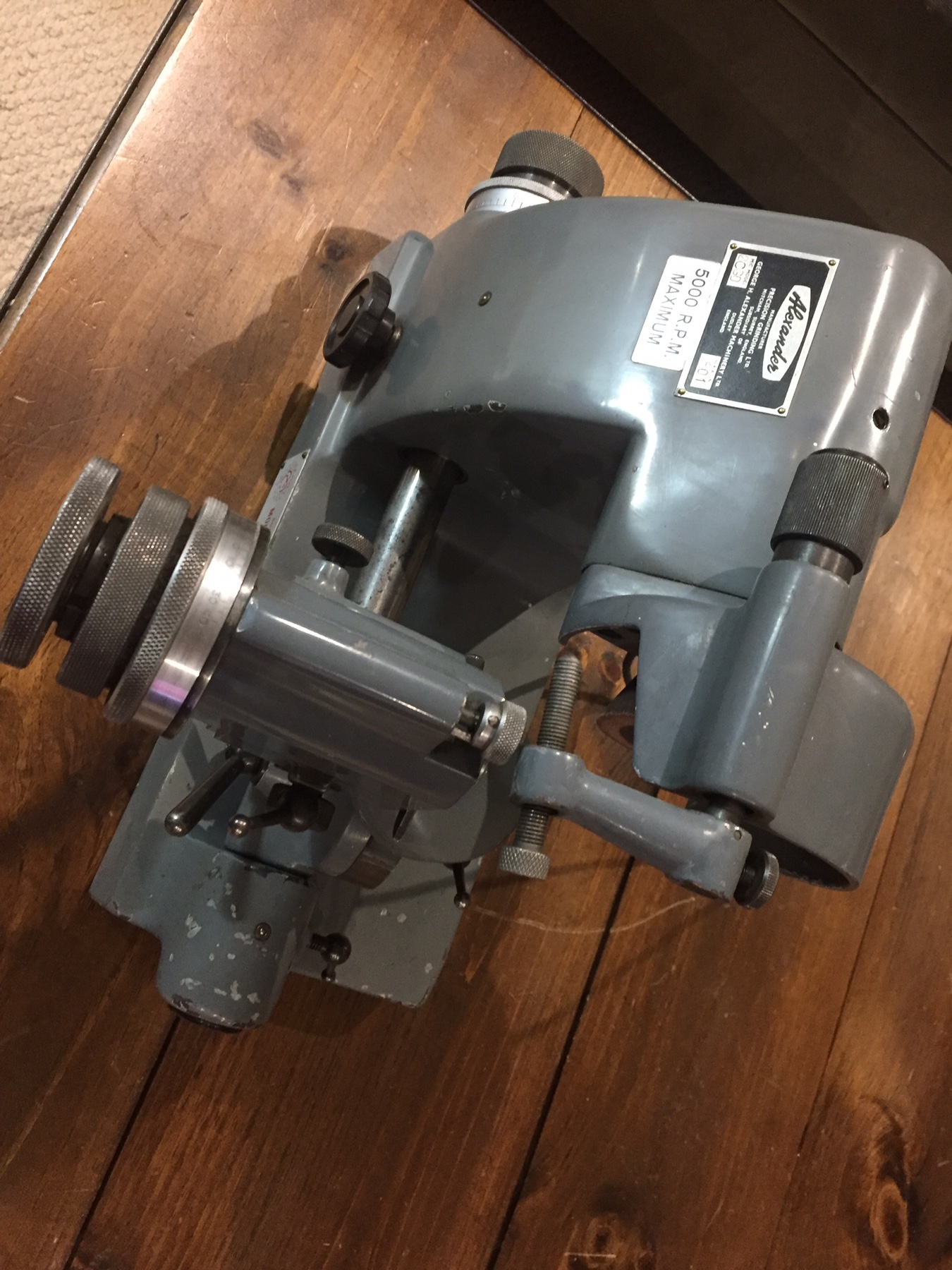

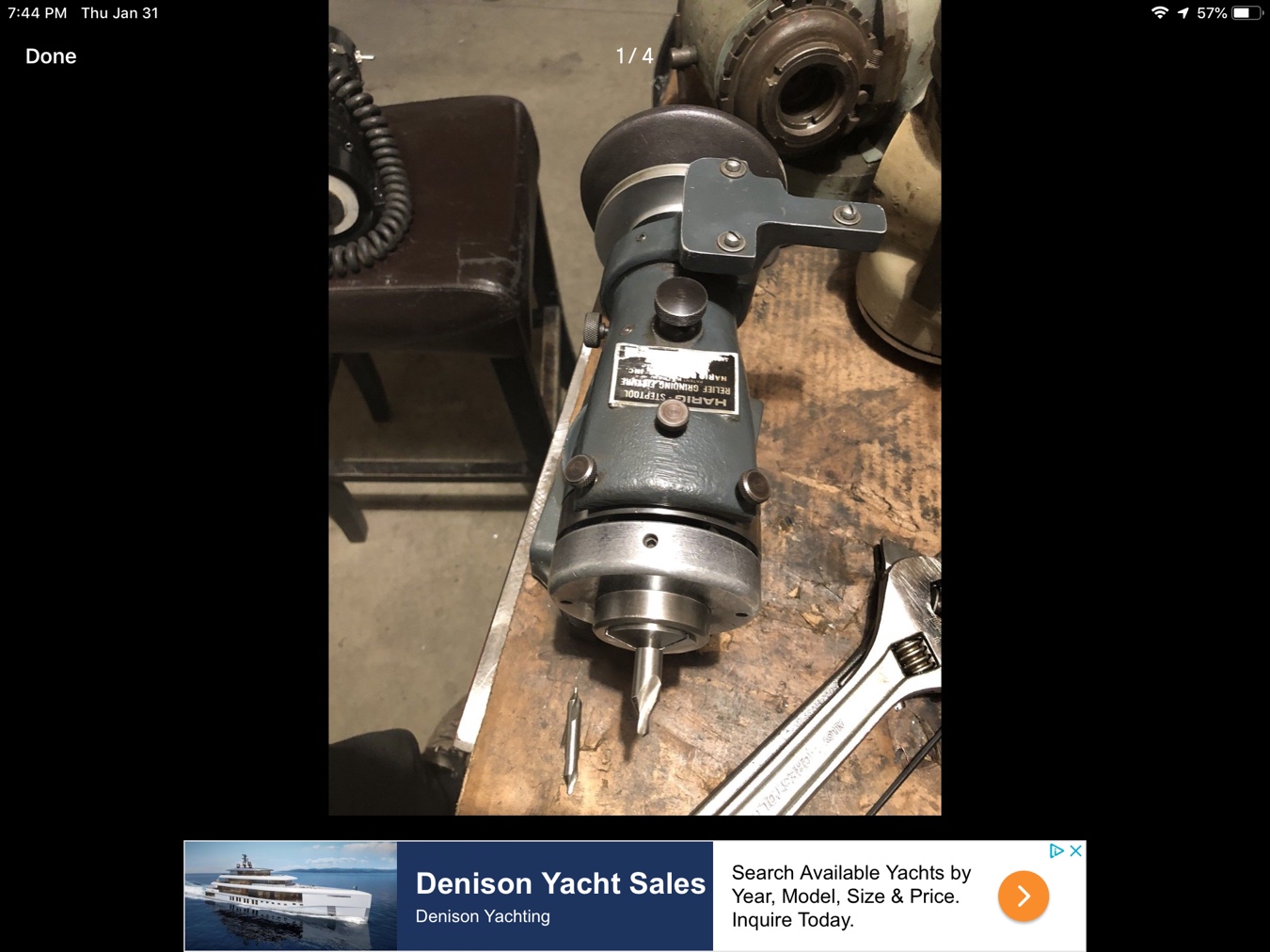

Hey everybody I need your help. About a year ago I acquired an Alexander 2CGD “D Bit” Cutter Grinder (allots an exact match to a Decker SO). I had in my head that it was used to sharpen milling cutters; out of ignorance. I soon learned that it isn’t. This past week I happened across a deal that I couldn’t pass up and acquired a Toycen Cuttermaster Journeyman DC tool and cutter grinder with air bearing attachment, and radius/bull nose attachment. Along with it I picked up a Harig Steptool and a Grindall No. 1. Pics of it all are attached. The Grindall is a pic from eBay because I don’t have one of my Grindall on my iPad.

I believe I have achieved an ability to sharpen almost any tool in my basement hobby shop. My question then is this. Is there any reason to keep the Alexander? I guess I really don’t understand what the Alexander is for. A couple friends have told me things that I can do with it but I don’t see how or why. Is this a tool that a basement shop guy will use? I will certainly be able to get what I have invested back out of it but I don’t “need” to sell it. Should I sell or keep it and why?

I appreciate every bit of input that anyone wants to throw at me. Thanks to you all for your thoughts.

Derek.

Sent from my iPad using Tapatalk

I believe I have achieved an ability to sharpen almost any tool in my basement hobby shop. My question then is this. Is there any reason to keep the Alexander? I guess I really don’t understand what the Alexander is for. A couple friends have told me things that I can do with it but I don’t see how or why. Is this a tool that a basement shop guy will use? I will certainly be able to get what I have invested back out of it but I don’t “need” to sell it. Should I sell or keep it and why?

I appreciate every bit of input that anyone wants to throw at me. Thanks to you all for your thoughts.

Derek.

Sent from my iPad using Tapatalk