- Joined

- Apr 8, 2013

- Messages

- 1,979

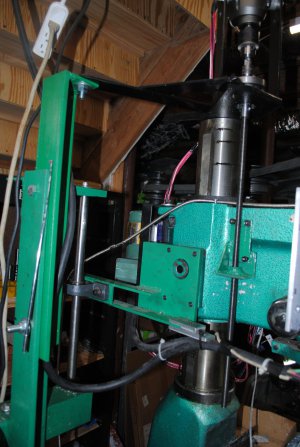

Here's some pix. I used a 6 ft piece of 3" x 3" x .500" angle iron attached to the stand to mount the ground rod. The hole the rod goes thru is oversize to allow dialing it in. I used the 4 bolt holes for the old manual crank head lift to mount the bracket that holds the pillow block. I wanted the indexing rod to be as far as possible from the column to minimize runout. When I built the powered head lift I added a piece of angle so I could tie it all together at the top of the column. Unlock the head, raise it, lower it back, lock the head again, and it repeats to .001inches. When the head is unlocked the tool will be stable but .005" from the locked position. If I'm doing a lot of drilling, tapping chamfering, ect that requires constant raising and lowering of the head I just leave it unlocked. The indexer is rigid enough to handle that on it's own.That's an interesting take, I'd love to see the whole thing. Is the rail bracket all one piece? What is it mounted to?

Thanks

Attachments

Last edited: