- Joined

- May 3, 2020

- Messages

- 229

I'm suspicious that something else is wrong with the x axis feed. Lever and hand wheel feeds have been used successfully for decades on production horizontal mills, and not just for cutting soft metals. Is there a lot of backlash in the axis? If you try to wobble it by hand, is there obvious movement? Internet wisdom says that backlash doesn't matter, but it really does if it is severe. Before expending a lot of effort on a lead screw conversion, I'd be tempted to try to cobble together some kind of temporary screw feed to test what is going on. A large C-clamp can be the start of such a test.

Good question. Let me check...

When I received the mill, I took apart the x-axis and cleaned it completely. I re-assembled and lubricated with way oil. The gib is tightened down as much as possible. There is a bit of stick-slip when I pull on the lever so it may be slightly tighter than necessary.

The pinion gear is held onto its shaft with a tapered pin, which was not driven home. That resulted in lash between the lever and the pinion. I've fixed that and it helped a lot. There is some lash in the rack/pinion. I just measured it now. I was going to measure lash of the table but it's really hard to move by hand. I put the indicator on the pinion and measured about 0.010" of total movement.

When I'm cutting, there is perceptible motion in the table but it's hard to figure out where it's coming from. The x-axis is tightened to the point that an 1/8 turn more on the gib-adjustment screws is a problem. The y-axis is similarly tight. And the z-axis, which both x and y are on, is locked tight. Still, if I put a good test indicator on the table, I can deflect the needle 2-3 thousandths in either direction with 50-80 lb of pressure on the table. If I press in the middle of the table, the deflection is closer to 0.001". Seems fairly squishy.

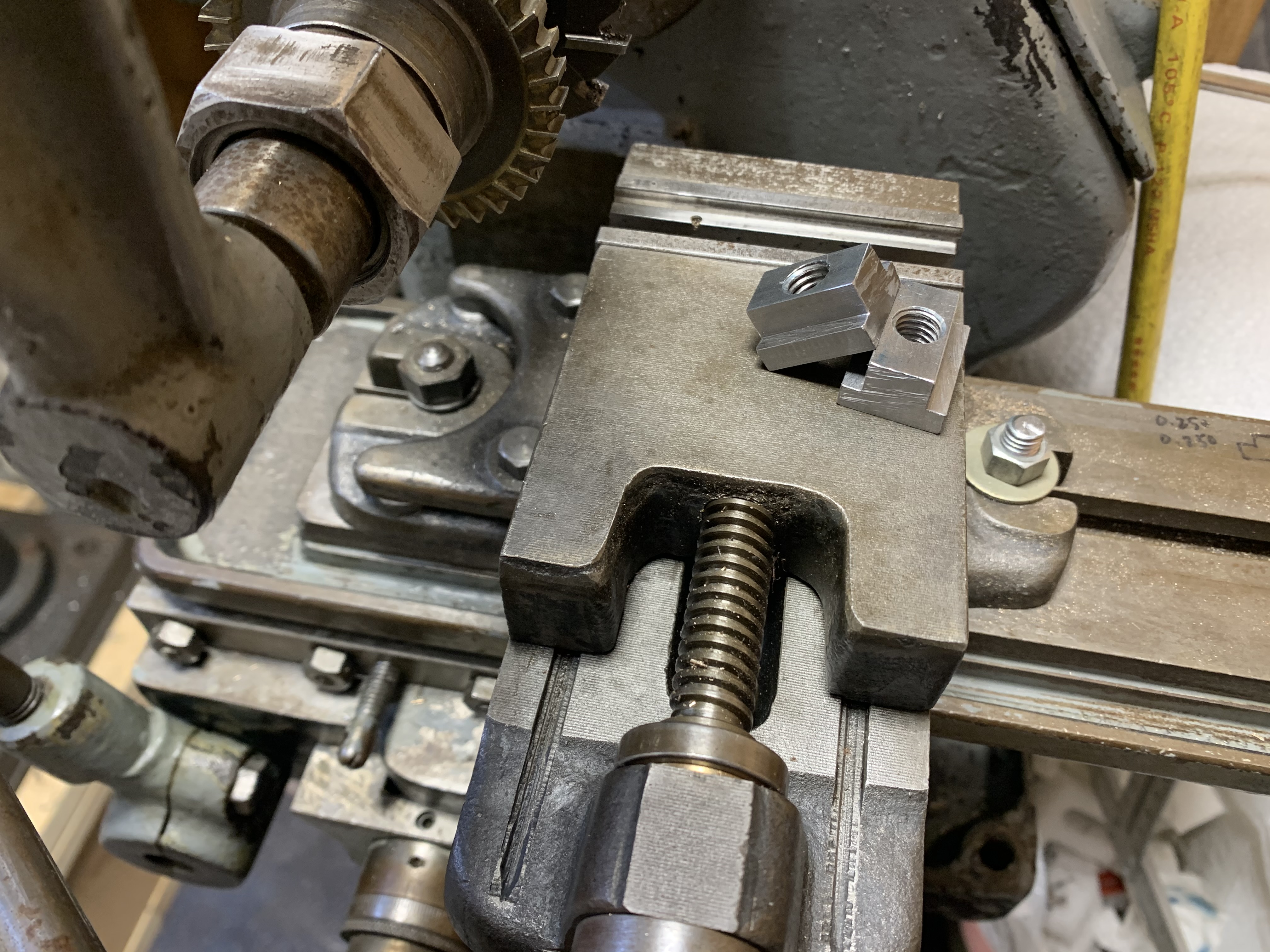

After reading you comment, I finished the T-nuts. Felt similar to machining brass, actually. I was as likely to jam the cutter and slip the belts with both materials. After tightening down the vise properly, there was no difference---still super twichy and difficult to feed without jamming. I tried a smaller cutter with more teeth, which also didn't help.

THEN, I measured the spindle runout. The spindle is running out 4--5 thou. This explains the trouble feeding, I think. It explains the pulsing I feel in the lever. And combined with the stick-slip of the x-axis, the feed is probably jerking, causing the cutter to bite too hard and slip the belts. From Machinery's Handbook, a few thou cut per tooth is a typical feed rate. So if I'm trying to feed normally on the low side of the cutter, when the high side of the cutter comes around, it's trying to take a huge bite. I noticed that I sometimes would get into a rhythm, advancing after the high side took a cut and slacking off a little when the high side came around again. It's 70 RPM and you can hear and feel that something is out of round.

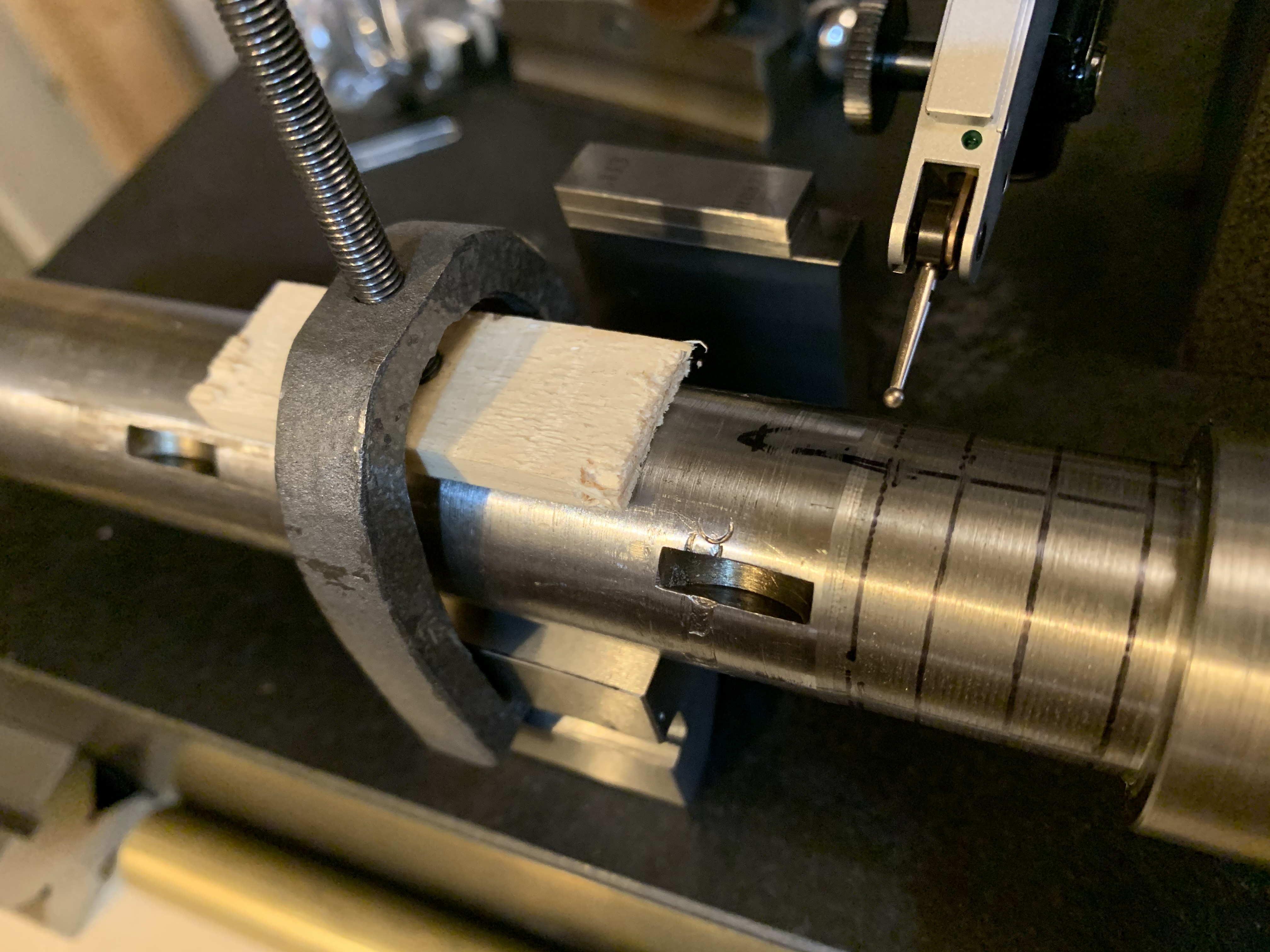

I've already check the arbor. The arbor seems perfect, on the surface plate. BUT the spindle is a train wreck. I'm getting 0.004" runout wherever I measure---in the bore, on the spindle nose, on the taper. I removed overarm, nut, and spacers, which made no difference. I tightened and loosened the bearing pre-load but nothing changed, whatever the setting. I measured with very light belt pressure and heavy belt pressure---maybe 0.0005 variation in runout. I measured the diameter of the spindle nose with a micrometer and got the same readings all around, within a few tenths. Is there an other explanation other than a bad bearing? Seems odd that the runout is bad at both ends of the spindle.

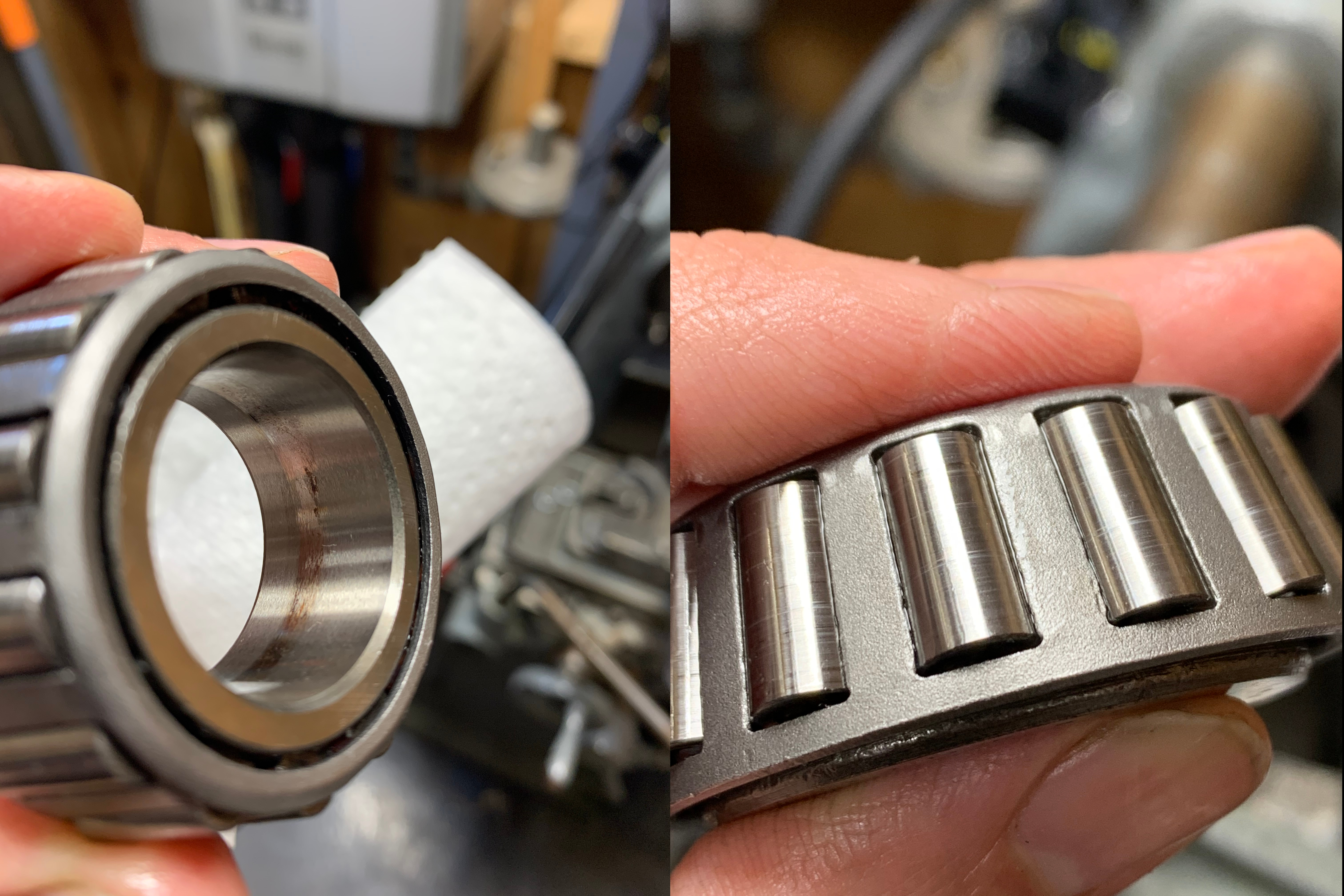

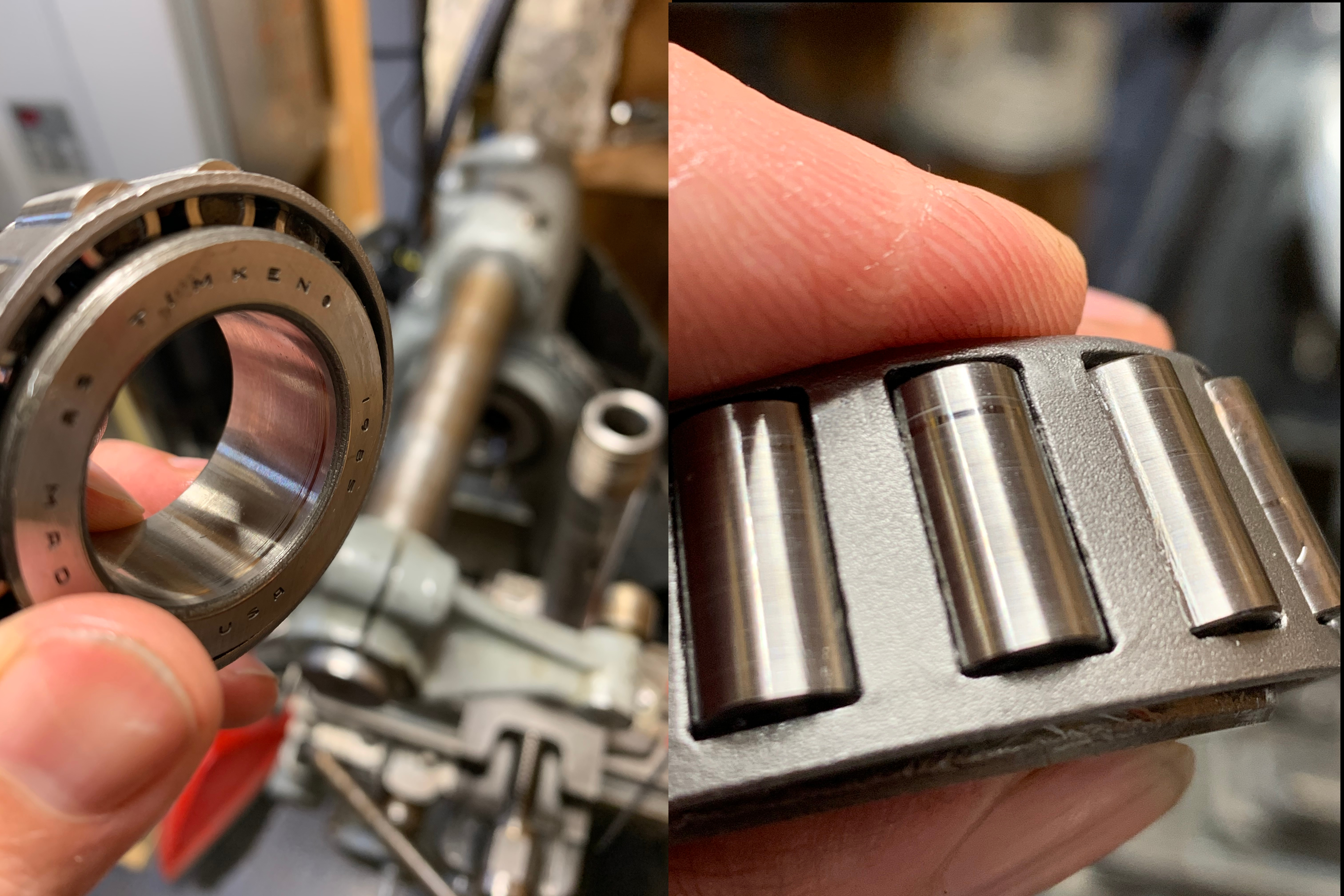

I pulled the spindle and bearings. Both inner races are too loose and are rubbing on the spindle. There are burnished lines on all of the rollers which, in my imagination, indicates a metal chip getting jammed between a roller and a race. Probably it was a metal that was softer than the bearing components. Abrasive wear looks different---more of a cloudy effect. See the p. 47, Figure 10 in the SKF failures-analysis publication. Abrasives, if I understand it, are very hard but mostly brittle. They don't burnish but catch on the roller, pulling the article under the contact patch. The abrasive particle then breaks, making even smaller abrasive particles. But I have distinct shiny rings on my rollers, not hazy tumbling abrasive patterns.

I ordered new bearings, just in case. Not sure if that will fix the problem.

I read some more about TIR and I can't see how the bearing could be causing consistent deflection at low-speed (30 RPM). So I measured the shaft. Where the front bearing touches the spindle shaft, near the nose, the spindle is out of round. To avoid errors from the spindle is mounted, I measured it with v-blocks (wide and narrow sides) and suspended on a rod between v-blocks. All measurements gave the same result---about 0.003 deviation from one side of the shaft to the other. The other end is better. These measurement correspond to the scuffing on the inner races, too.

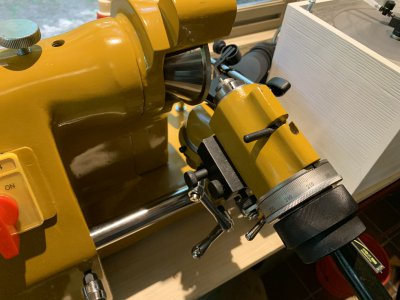

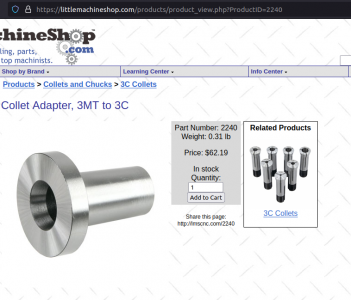

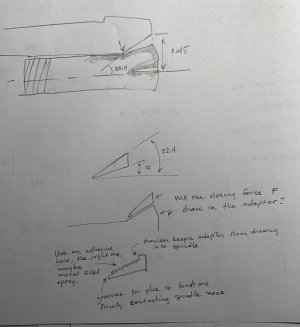

So now what? Shim the bearing? Make a new spindle? I'm not super confident about turning a new spindle. Haven't turned between centers before and my first single-point threading on the 9x20 was a disaster. It's a long bore, far longer than I've ever done. It would be an opportunity to change the collets... Maybe instead I could true the shaft on the lathe, make a bushing, split it, and press the bearing over the bushing.