- Joined

- Feb 27, 2015

- Messages

- 105

Hi,

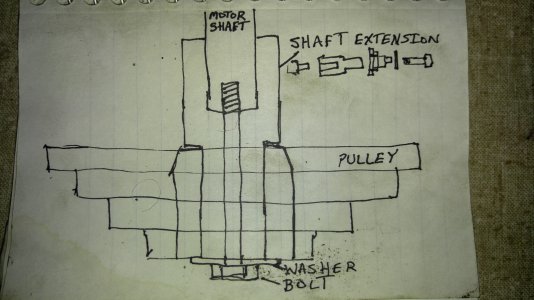

I have got a motor pulley that I have had to make an adapter for to mount to a motor. The motor shaft has a keyway and the pulley had a keyway. I had to turn down the motor shaft from 1 1/8" to 15/16" because the pulley shaft was 1". The motor shaft would only fit 1" down into the pulley so I had to extend the shaft to 3.75". I opened the pulley diameter, which was originally 1", to 1.3" and could open it up about 1/8" more.

So I have got the adapter fitted snuggly to the motor shaft. I am going to attach the adapter to the motor then chuck it up and turn the adapter down to fit the pulley. The pulley is 4 step with the largest being approximately 11".

So the question - will drilling and pinning the pulley and adapter to the motor shaft in 2 places 90 degrees apart be satisfactory to hold it all together. The pin diameter would be 1/4". I would also use red loctite but I am not sure if it is necessary. I could tack weld the pins in place also. The motor will drive the pulley at up to 5000rpm (inverter vector motor) on my Gorton mill.

I don't think I am asking this all correctly so I am open to suggestions. The big question is the balance of the pulley, motor shaft, and adapter. I searched and didn't come up with much and neither did looking it up in the Machinery Handbook.

I am susceptible to overthinking things so any suggestions are appreciated!

OR I could thread the stick out from the pulley end and bolt that up?

I have got a motor pulley that I have had to make an adapter for to mount to a motor. The motor shaft has a keyway and the pulley had a keyway. I had to turn down the motor shaft from 1 1/8" to 15/16" because the pulley shaft was 1". The motor shaft would only fit 1" down into the pulley so I had to extend the shaft to 3.75". I opened the pulley diameter, which was originally 1", to 1.3" and could open it up about 1/8" more.

So I have got the adapter fitted snuggly to the motor shaft. I am going to attach the adapter to the motor then chuck it up and turn the adapter down to fit the pulley. The pulley is 4 step with the largest being approximately 11".

So the question - will drilling and pinning the pulley and adapter to the motor shaft in 2 places 90 degrees apart be satisfactory to hold it all together. The pin diameter would be 1/4". I would also use red loctite but I am not sure if it is necessary. I could tack weld the pins in place also. The motor will drive the pulley at up to 5000rpm (inverter vector motor) on my Gorton mill.

I don't think I am asking this all correctly so I am open to suggestions. The big question is the balance of the pulley, motor shaft, and adapter. I searched and didn't come up with much and neither did looking it up in the Machinery Handbook.

I am susceptible to overthinking things so any suggestions are appreciated!

OR I could thread the stick out from the pulley end and bolt that up?

Last edited: