- Joined

- Nov 21, 2010

- Messages

- 1,602

The job, a valve in block engine to be counter bored for valve seat inserts. The depth cut is no problem, but getting the OD is, because

the OD of the new seats are comming in at + .001 .0015 or -.001 .0015 whatever. These are press fit and the new seats are in the shop

freezer. I cant screw this up. My problem is sneakin up to this press fit. The main problem is the boring head being in the way because I do want minimal quill hangin down. Inside mic no good I cant read it, snap gauge the fat end is too fat, really too big cause the depth is

.215. Inside calipers, dial calipers digi calipers all I woundnt trust my life on. My only way is-the bottom of the new seats are champered

and Ive been eyeballing that. But one insert went in with a brass hammer although I will stake it. So each operation has to be tailer made.

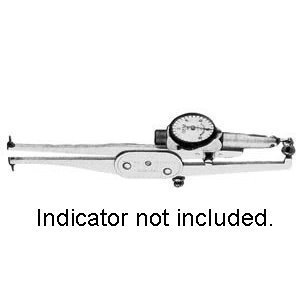

so the question #1 no room, #I cant see it and three I searched all sites for some kind of thin snap gage with no avail and #4 I think I will

machine a polished ball end gage..I just cant find any snaps with small balls? I'd show exactly what I need but my new two week old scanner

printer already took a dump. An 90 degree forked ball indicator is what i need never seen one.

the OD of the new seats are comming in at + .001 .0015 or -.001 .0015 whatever. These are press fit and the new seats are in the shop

freezer. I cant screw this up. My problem is sneakin up to this press fit. The main problem is the boring head being in the way because I do want minimal quill hangin down. Inside mic no good I cant read it, snap gauge the fat end is too fat, really too big cause the depth is

.215. Inside calipers, dial calipers digi calipers all I woundnt trust my life on. My only way is-the bottom of the new seats are champered

and Ive been eyeballing that. But one insert went in with a brass hammer although I will stake it. So each operation has to be tailer made.

so the question #1 no room, #I cant see it and three I searched all sites for some kind of thin snap gage with no avail and #4 I think I will

machine a polished ball end gage..I just cant find any snaps with small balls? I'd show exactly what I need but my new two week old scanner

printer already took a dump. An 90 degree forked ball indicator is what i need never seen one.