- Joined

- Jan 6, 2017

- Messages

- 1,214

This project required the use of nearly all of my machines. Except maybe the welder and air compressor.

Inspired by the wicked edge pro series.

I bought the clamp from WE, and fabricated the rest using my Birmingham 13x40 lathe, PM935 mill, and G0704 CNC build.

Drilling and facing.

Testing the first couple parts.

After a few more parts.

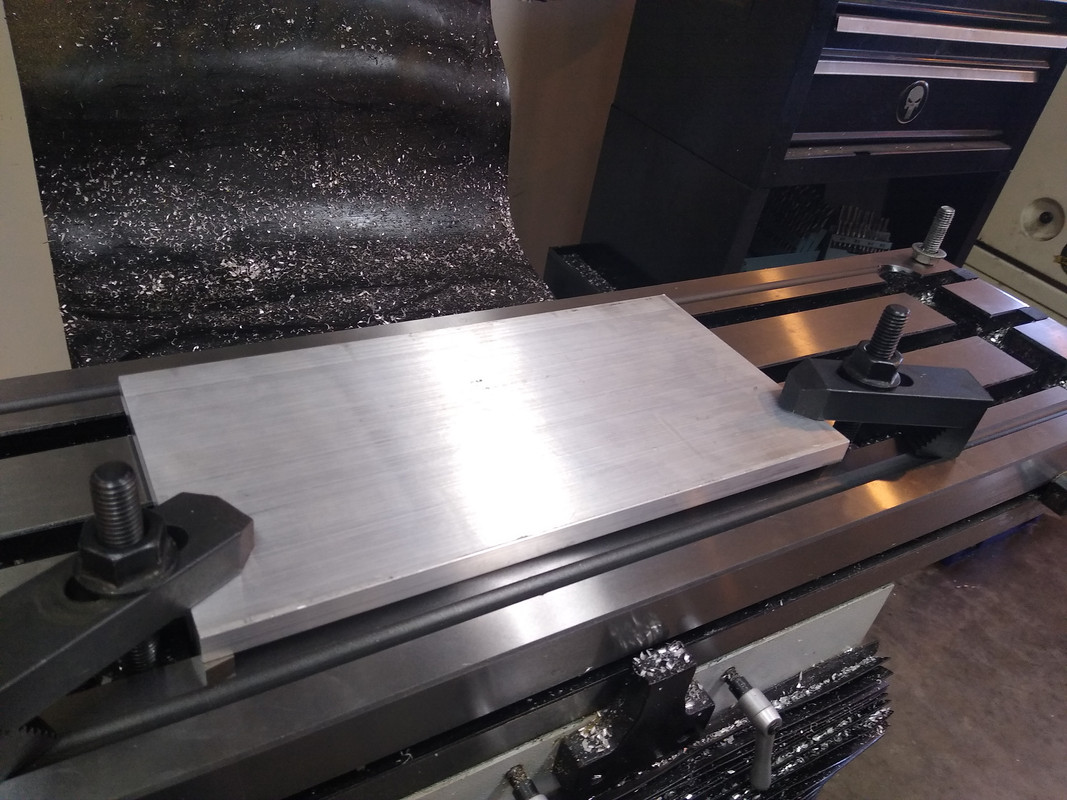

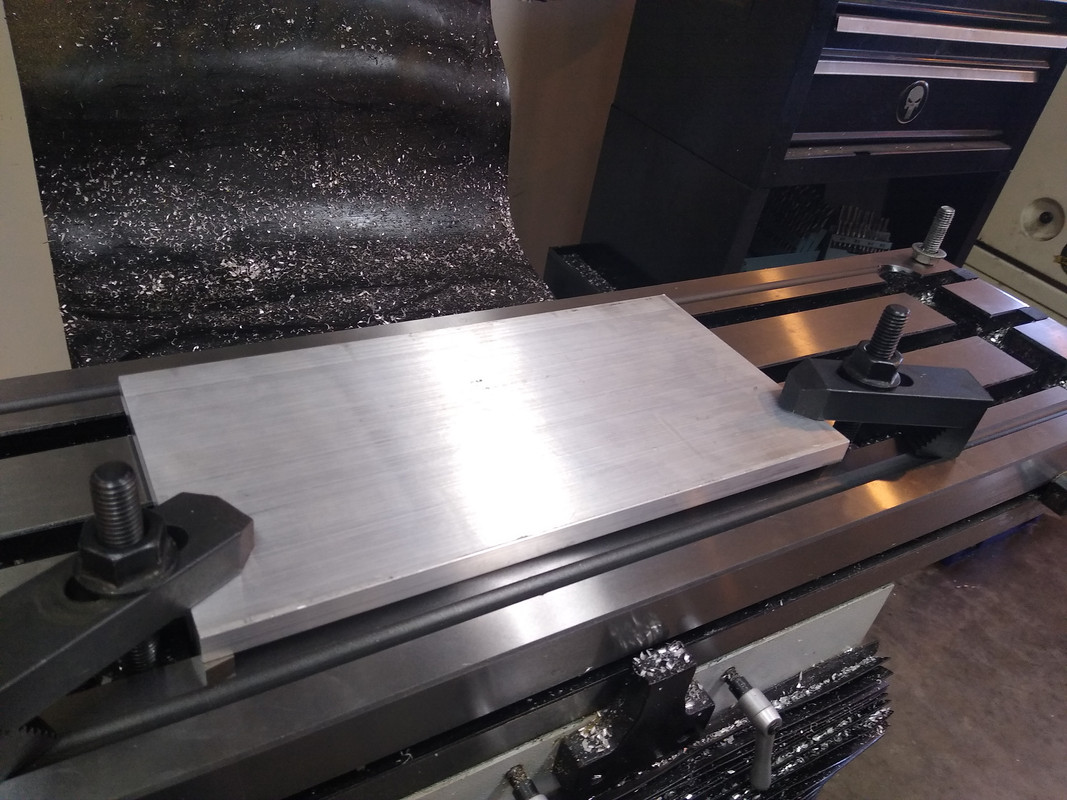

Roughing.

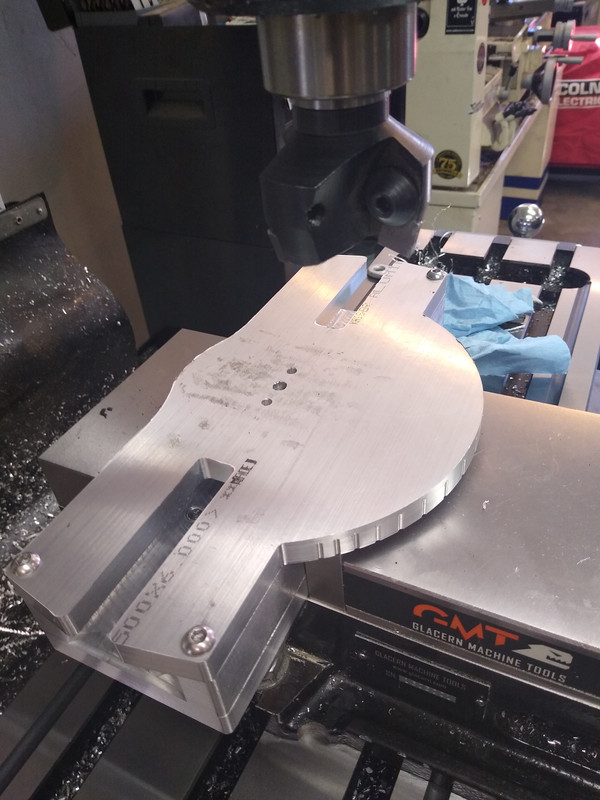

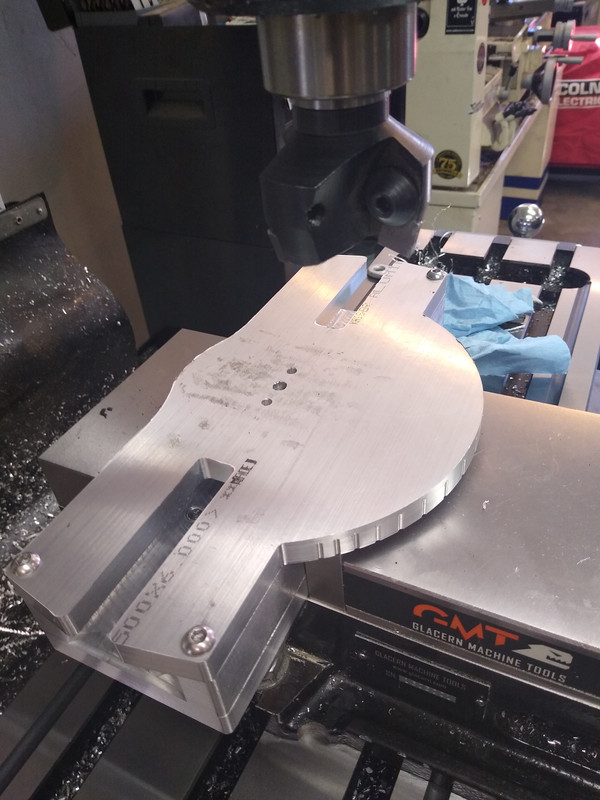

Finishing

Chamfering.

More chamfering.

https://youtu.be/RNSuBW-Dbtc

Setting Z to engrave.

https://youtu.be/L7b8nRSk1pE

Engraving.

https://youtu.be/dAFyQ1GSmXQ

More engraving.

https://youtu.be/mhaRAXxUp7w

Testing detents after assembly.

https://youtu.be/V80Aga3u-Ww

Testing on a Shun kitchen knife.

https://youtu.be/_x72nSApWl8

It works great with edge pro Shapton stones epoxied to 3d printed mounts, but probably cost more in time and materials than just buying one.

Inspired by the wicked edge pro series.

I bought the clamp from WE, and fabricated the rest using my Birmingham 13x40 lathe, PM935 mill, and G0704 CNC build.

Drilling and facing.

Testing the first couple parts.

After a few more parts.

Roughing.

Finishing

Chamfering.

More chamfering.

https://youtu.be/RNSuBW-Dbtc

Setting Z to engrave.

https://youtu.be/L7b8nRSk1pE

Engraving.

https://youtu.be/dAFyQ1GSmXQ

More engraving.

https://youtu.be/mhaRAXxUp7w

Testing detents after assembly.

https://youtu.be/V80Aga3u-Ww

Testing on a Shun kitchen knife.

https://youtu.be/_x72nSApWl8

It works great with edge pro Shapton stones epoxied to 3d printed mounts, but probably cost more in time and materials than just buying one.