OK, with much advice/support/tips from a couple of my machining buddies, here I am trying Knurling Titanium.

Now, being that I am not all that smart, instead of starting with steel, or with CP2 (Grade 2), I am stubborn enough of trying this on 6al-4v.

I am using my Dorian cut knurler, and using a calculator for setting up the diameter based on the knurler at hand:

PM12x36 lathe

Dorian Cut knurler, with RS 25 wheels

Ti Bar Dia = 0.650"

Carriage speed = 0.012 IPR

Spindle Speed = 65 RPM

Infeed = 0.018" (all in one pass)

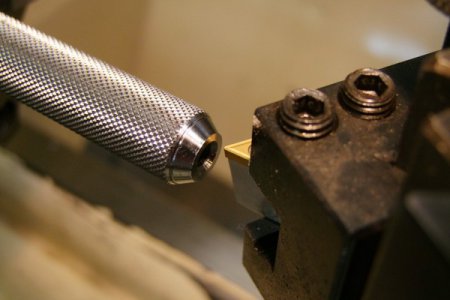

Getting the diameter set (per calculator):

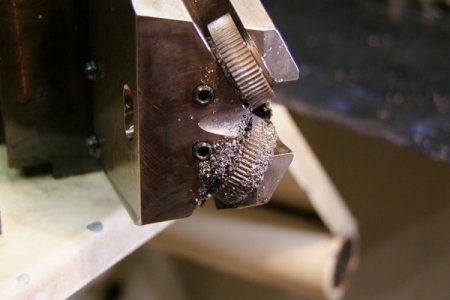

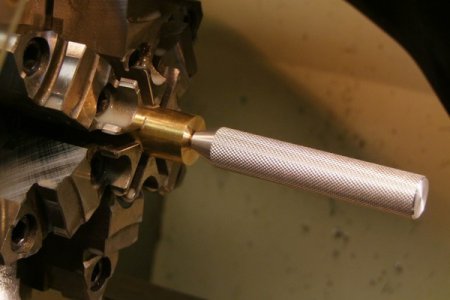

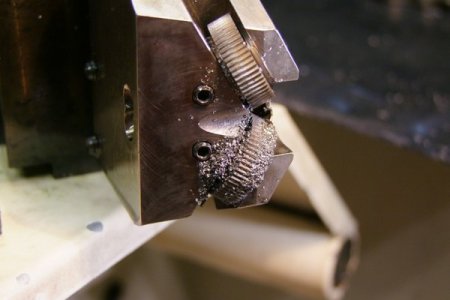

Cutting a 60 deg area to help ease/start the knurlers:

Setup for my PM12x36 (back gears were left as when I cut 20TPI threads, but the front dials were adjusted to 0.012 IPR as shown in these pictures):

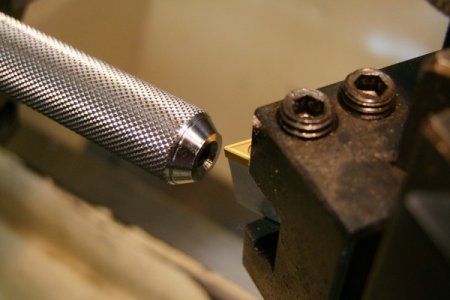

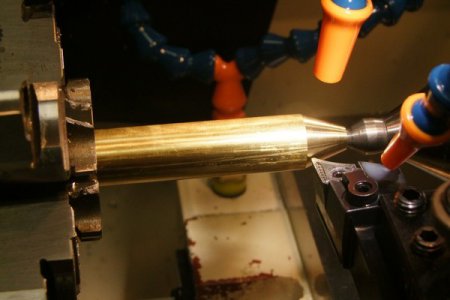

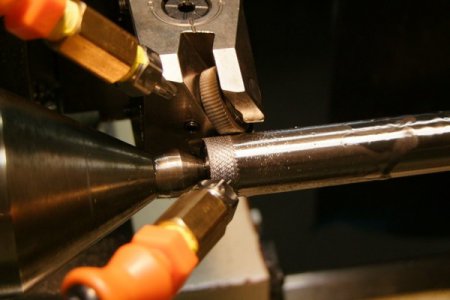

Starting to "cut" threads, various angles (you know me, I can't help but take lots of pictures!):

Infeed:

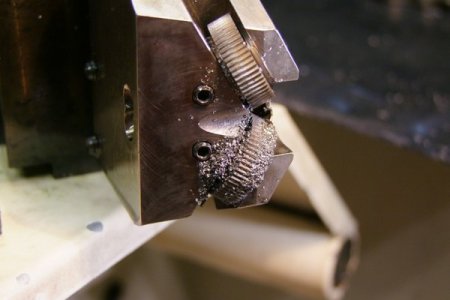

And yes, we are most definitely cutting metal away, but I am getting a little bit of binding on the cutters:

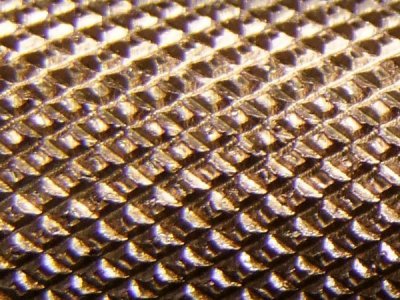

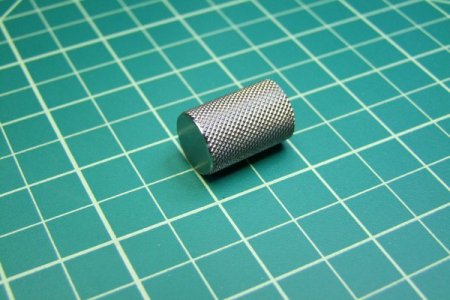

After a single pass. Obviously not great, but not too bad as a starting point:

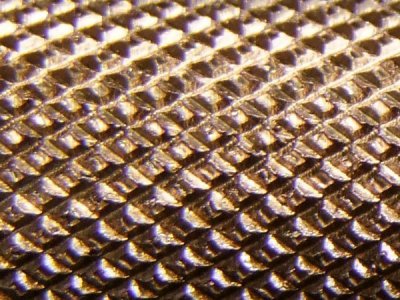

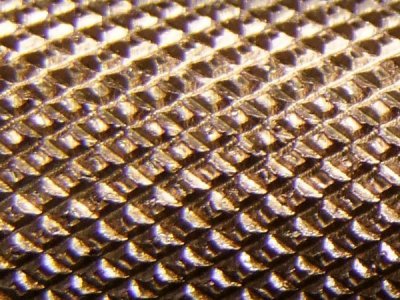

Here in the cropped picture you can see that the grooves being cut are not quite "even", and that there is also some metal being displaced as well - note this is "as is" - I have not cleaned the piece):

Short movie:

You Tube Movie

- - - Updated - - -

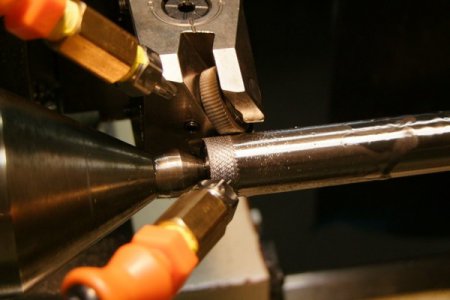

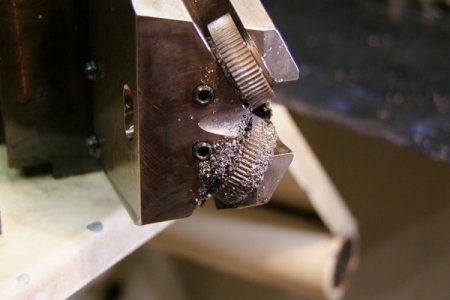

Now that I have the flood coolant running, I tried again the cut knurler - much, much better. Here on the left I am setting up the OD - the portion on the right was the one I did last time which came out OK:

Just two passes, one at 0.008" and the second (a cleaning pass) at 0.010":

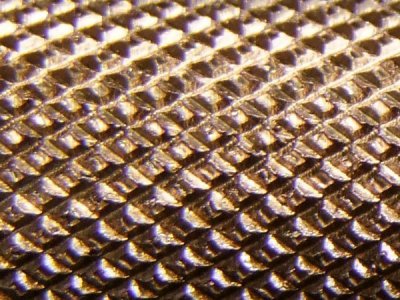

The finish was even better (new on the left, and previous on the right):

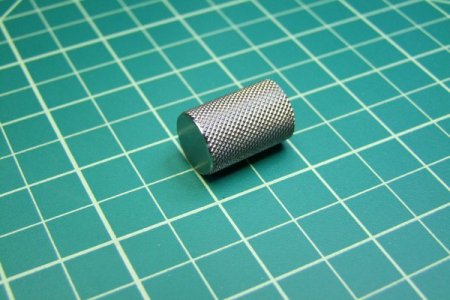

The knurling came out nice enough that I decided to go ahead and make a DE handle out of this portion, so I am cutting of the previous piece, then cleaned it up:

Not too bad for a newbie:

Not that anyone would shave with it, but it looks cool:

Here I started drilling and tapping the new DE handle:

Now, being that I am not all that smart, instead of starting with steel, or with CP2 (Grade 2), I am stubborn enough of trying this on 6al-4v.

I am using my Dorian cut knurler, and using a calculator for setting up the diameter based on the knurler at hand:

PM12x36 lathe

Dorian Cut knurler, with RS 25 wheels

Ti Bar Dia = 0.650"

Carriage speed = 0.012 IPR

Spindle Speed = 65 RPM

Infeed = 0.018" (all in one pass)

Getting the diameter set (per calculator):

Cutting a 60 deg area to help ease/start the knurlers:

Setup for my PM12x36 (back gears were left as when I cut 20TPI threads, but the front dials were adjusted to 0.012 IPR as shown in these pictures):

Starting to "cut" threads, various angles (you know me, I can't help but take lots of pictures!):

Infeed:

And yes, we are most definitely cutting metal away, but I am getting a little bit of binding on the cutters:

After a single pass. Obviously not great, but not too bad as a starting point:

Here in the cropped picture you can see that the grooves being cut are not quite "even", and that there is also some metal being displaced as well - note this is "as is" - I have not cleaned the piece):

Short movie:

You Tube Movie

- - - Updated - - -

Now that I have the flood coolant running, I tried again the cut knurler - much, much better. Here on the left I am setting up the OD - the portion on the right was the one I did last time which came out OK:

Just two passes, one at 0.008" and the second (a cleaning pass) at 0.010":

The finish was even better (new on the left, and previous on the right):

The knurling came out nice enough that I decided to go ahead and make a DE handle out of this portion, so I am cutting of the previous piece, then cleaned it up:

Not too bad for a newbie:

Not that anyone would shave with it, but it looks cool:

Here I started drilling and tapping the new DE handle: