- Joined

- Oct 31, 2016

- Messages

- 2,643

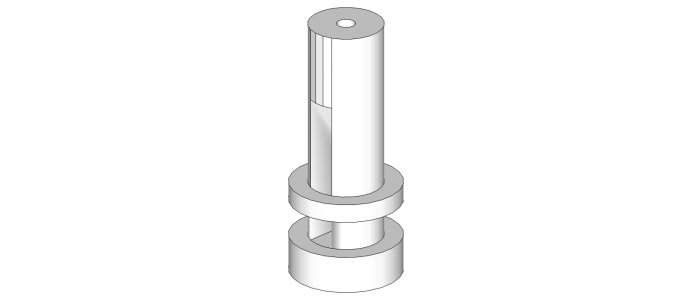

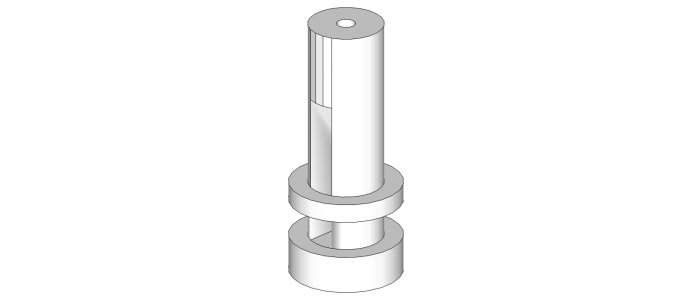

I think that just about everyone with an older lather has one of these contraptions. I do and it is a pain to use. Yet sometimes you have to use it. I recently had to dig mine out and use it to get into a tight corner. Winky's Workshop recently made one and came up with a novel way to adjust the height of the tool bit. An adjustable collar that you can screw to any height you need to get the tool bit on center line. A whole lot easier to use than fiddling with a bunch of shims and rockers. I added this to my project list.

This evening I got my lantern out and was thinking about the dimensions to make the collar. I realized that the collar can only adjust through a small range to keep enough threads engaged to support the forces against the collar. I could solve that by threading the body of the lantern. No limit on the number of threads that would be engaged. The threads on the collar would always be completely engaged. Off to the lathe to check on my idea and discovered that the collar has to be held tight to the compound to keep the lantern from flopping around. Back to brainstorming on this. This is what I came up with. Two collars. One to hold the lantern tight to the compound and one to set the height of the tool bit. One thing that I don't know is how hard would it be to thread the body of the lantern and another would threading the body negatively impact the strength. I could always use very fine threads.

I know that I must have too much time on my hands. But I have a narrow window to get things done before it will get to cold to be out in the garage.

This evening I got my lantern out and was thinking about the dimensions to make the collar. I realized that the collar can only adjust through a small range to keep enough threads engaged to support the forces against the collar. I could solve that by threading the body of the lantern. No limit on the number of threads that would be engaged. The threads on the collar would always be completely engaged. Off to the lathe to check on my idea and discovered that the collar has to be held tight to the compound to keep the lantern from flopping around. Back to brainstorming on this. This is what I came up with. Two collars. One to hold the lantern tight to the compound and one to set the height of the tool bit. One thing that I don't know is how hard would it be to thread the body of the lantern and another would threading the body negatively impact the strength. I could always use very fine threads.

I know that I must have too much time on my hands. But I have a narrow window to get things done before it will get to cold to be out in the garage.