- Joined

- Dec 3, 2013

- Messages

- 1,844

This is my last lathe project before moving my lathe to the new house.

4" wide by 7" diameter aluminum wheel. Cross section of all elements is .2". I started by squaring up the ends of the rough stock. Some how material houses are incapable of maintaining their equipment to cut anything reasonably straight. My cheapo HF horizontal band-saw will cut a 6" diameter stock within 1/32". This was 1/4"+ out of square so I used a live center to support the stock on the fist end.

After the rough stock was trued up I did the center bore. Center bore is 1.001" +0" -.0005" to be glued to a precision shaft. After boring the center the bulk of the material was roughed out on a CNC mill to within .05" of finish. (sorry no photos)

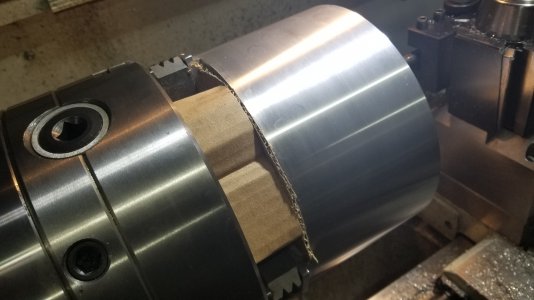

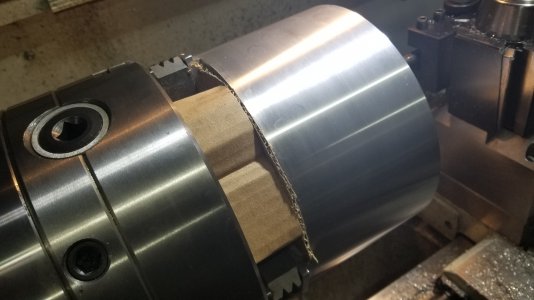

After the mill work the wheel was mounted on a precision ground mandrel for final turning. The wheel will be spun up to 6K rpm so we wanted it to be as concentric as possible. One thing I had not counted on was how it would react to turning with most of the material removed. When I tried to make a cut on the outer diameter the harmonics were so bad it was not turnable due to extreme chatter. Squealed like a mother too. Tapping it was like tapping a tuning fork.

This was the start of a .005" skim pass. Ugh!

After mulling over what to do I decided to try packing the backside with plumbers putty to provide some mass and dampening. Worked perfect! I did find it necessary to use some cardboard and tape to keep the putty in place while turning otherwise it wants to escape. I also made some aluminum shims to fit between the back edge of the wheel and chuck jaws. The shims were double stick taped to the jaws and then turned to provide a .001" compression on the wheel edge.

The inside web has a .26" fillet so I had to grind a form tool to do those.

Success!

4" wide by 7" diameter aluminum wheel. Cross section of all elements is .2". I started by squaring up the ends of the rough stock. Some how material houses are incapable of maintaining their equipment to cut anything reasonably straight. My cheapo HF horizontal band-saw will cut a 6" diameter stock within 1/32". This was 1/4"+ out of square so I used a live center to support the stock on the fist end.

After the rough stock was trued up I did the center bore. Center bore is 1.001" +0" -.0005" to be glued to a precision shaft. After boring the center the bulk of the material was roughed out on a CNC mill to within .05" of finish. (sorry no photos)

After the mill work the wheel was mounted on a precision ground mandrel for final turning. The wheel will be spun up to 6K rpm so we wanted it to be as concentric as possible. One thing I had not counted on was how it would react to turning with most of the material removed. When I tried to make a cut on the outer diameter the harmonics were so bad it was not turnable due to extreme chatter. Squealed like a mother too. Tapping it was like tapping a tuning fork.

This was the start of a .005" skim pass. Ugh!

After mulling over what to do I decided to try packing the backside with plumbers putty to provide some mass and dampening. Worked perfect! I did find it necessary to use some cardboard and tape to keep the putty in place while turning otherwise it wants to escape. I also made some aluminum shims to fit between the back edge of the wheel and chuck jaws. The shims were double stick taped to the jaws and then turned to provide a .001" compression on the wheel edge.

The inside web has a .26" fillet so I had to grind a form tool to do those.

Success!