- Joined

- Dec 24, 2020

- Messages

- 1,026

I'm getting ready to start outfitting a lathe I bought that didn't come with any provision for using collets. I don't expect that will be a primary use, but want to have the capability.

Right now I don't tend to make any significant runs of the same item...usually one or two and done. I'm also not worried about speed since I'm not doing any sort of production.

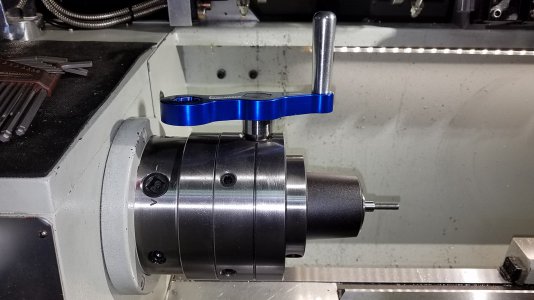

With that as a background, it seems I've got three choices that will all do the job...buy a collet adapter and manual closer, buy a 5C collet chuck (I have a pretty good set of 5C collets) or consider something like a Jacob's Rubberflex chuck (I have about half a complete set of Rubberflex collets that came with a prior lathe).

It seems like they'll all cost me about the same amount of money give or take so it probably comes down to convenience and accuracy/repeatability.

I'm sort of leaning towards a 5C chuck and maybe the adjustable set-true style, but I'm far from decided. From an accuracy/repeatability standpoint do the other choices offer any advantages? Anything else I'm not considering? I'm not in any rush, so I can wait and watch for deals as well.

Right now I don't tend to make any significant runs of the same item...usually one or two and done. I'm also not worried about speed since I'm not doing any sort of production.

With that as a background, it seems I've got three choices that will all do the job...buy a collet adapter and manual closer, buy a 5C collet chuck (I have a pretty good set of 5C collets) or consider something like a Jacob's Rubberflex chuck (I have about half a complete set of Rubberflex collets that came with a prior lathe).

It seems like they'll all cost me about the same amount of money give or take so it probably comes down to convenience and accuracy/repeatability.

I'm sort of leaning towards a 5C chuck and maybe the adjustable set-true style, but I'm far from decided. From an accuracy/repeatability standpoint do the other choices offer any advantages? Anything else I'm not considering? I'm not in any rush, so I can wait and watch for deals as well.