After recently purchasing my 10F TV36 I’m not really au fait with what should or shouldn’t happen when in use.

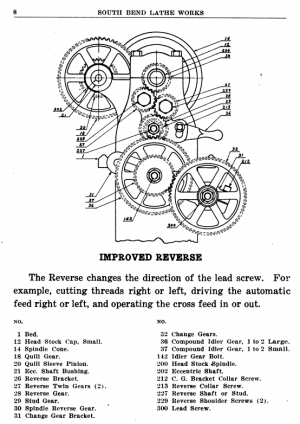

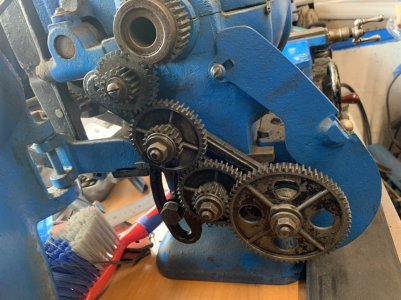

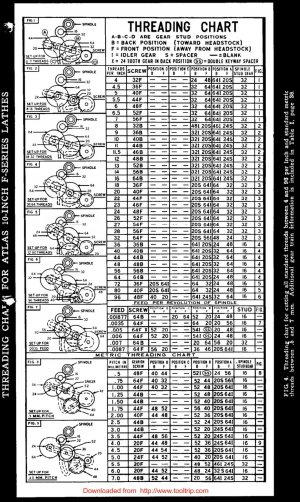

I’ve noticed even without the drive selected on the left hand lever, my lead screw is still turning and sometimes moving the carriage if it’s locked with the half nuts. I’m thinking it may be due to the banjo/gear meshing? What’s wrong with my set up? I’m sure it didn’t do this when it was collected and after removing a few of the gears I never set the mesh with paper. Could this be my problem?

I’ve noticed even without the drive selected on the left hand lever, my lead screw is still turning and sometimes moving the carriage if it’s locked with the half nuts. I’m thinking it may be due to the banjo/gear meshing? What’s wrong with my set up? I’m sure it didn’t do this when it was collected and after removing a few of the gears I never set the mesh with paper. Could this be my problem?