- Joined

- Jan 7, 2016

- Messages

- 3,267

Yeah, that was me.Somone asked about Octoprint earlier. I'm sitting at work, monitoring a 10 hour print of an Er32 collet rack.This one is the second attempt. The first try this monring didn't stick to the bed in one corner. My fault, didn't clean the bed all the way to the edges. I was able to see the issue and abort the print while sitting in the doctor's office. When I stopped by the house afterward I was able to CLEAN and restart.

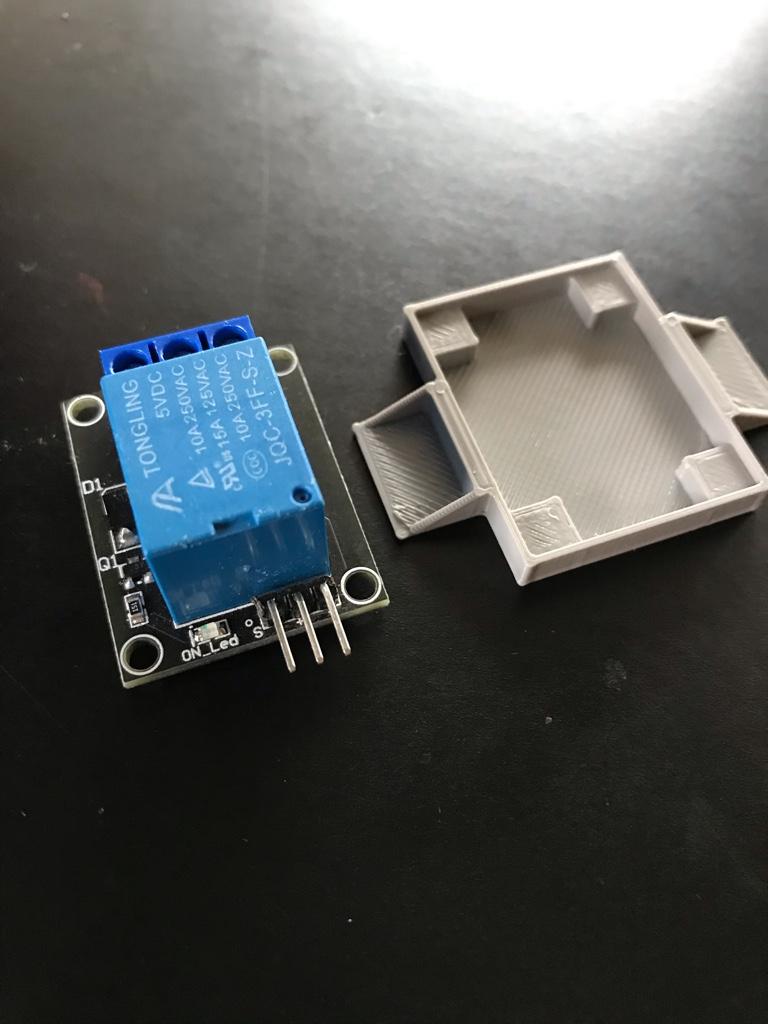

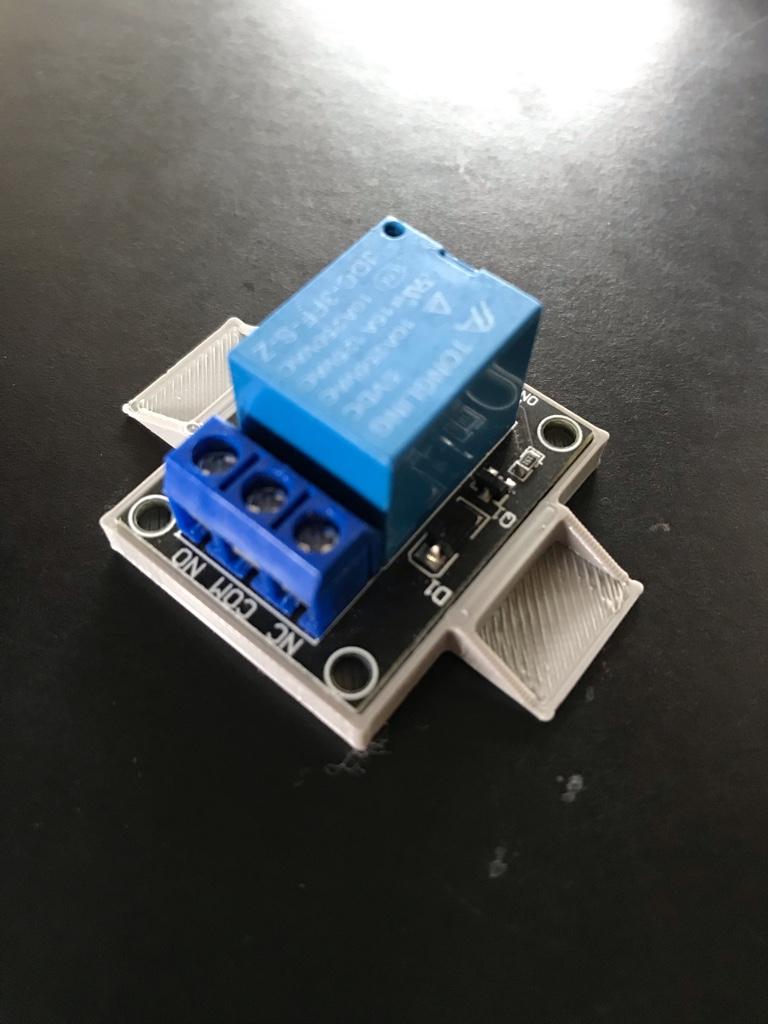

View attachment 356939

I am glad you brought that back up. I need to look into it.