- Joined

- Mar 26, 2018

- Messages

- 8,407

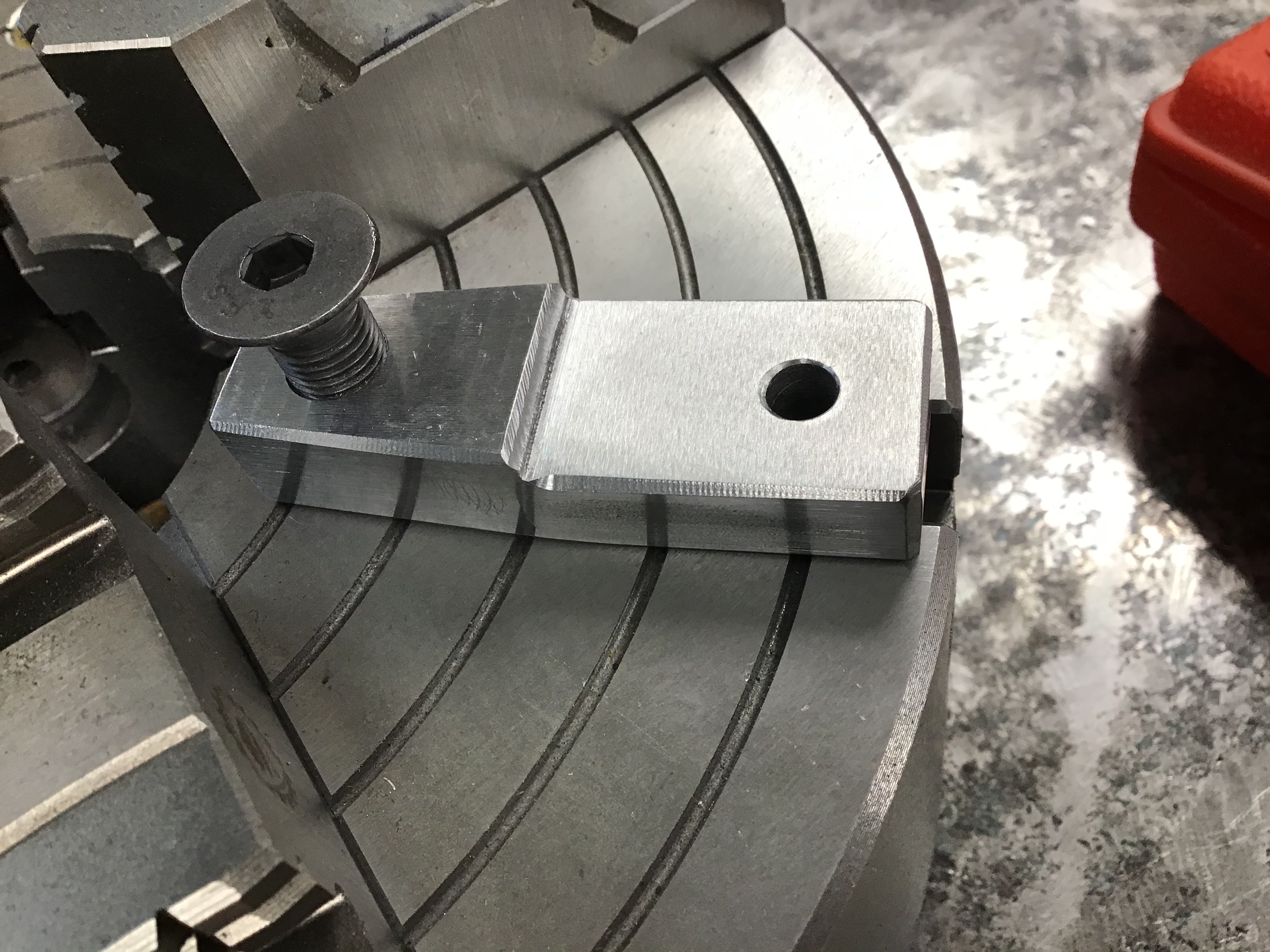

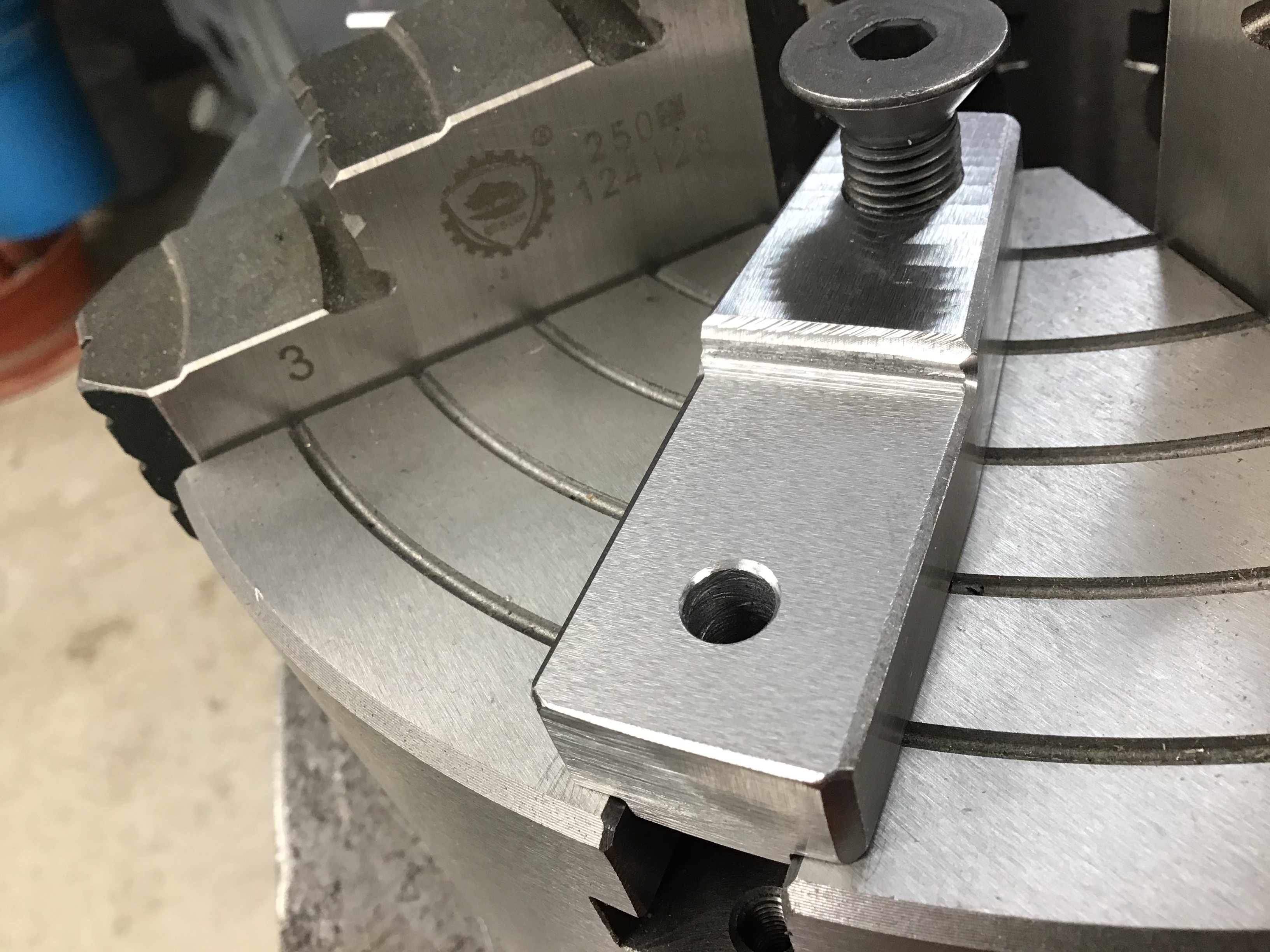

I’m making these chuck stand offs, as you can see, the finish quality is quite different.

All I did was dress the wheel. I don’t understand why I get the oscillating pattern.

It goes away after I dress.

Tomorrow I’m going to try a different wheel.

This is an open grain 46 J Radiac. Red.

I have a white 46 H I’m going to try, I’ve had spectacular finishes with that wheel.

This is annealed 4140. I’m going to harden when complete.

All I did was dress the wheel. I don’t understand why I get the oscillating pattern.

It goes away after I dress.

Tomorrow I’m going to try a different wheel.

This is an open grain 46 J Radiac. Red.

I have a white 46 H I’m going to try, I’ve had spectacular finishes with that wheel.

This is annealed 4140. I’m going to harden when complete.