- Joined

- Jan 20, 2018

- Messages

- 5,621

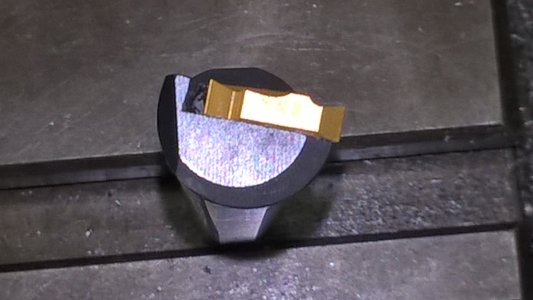

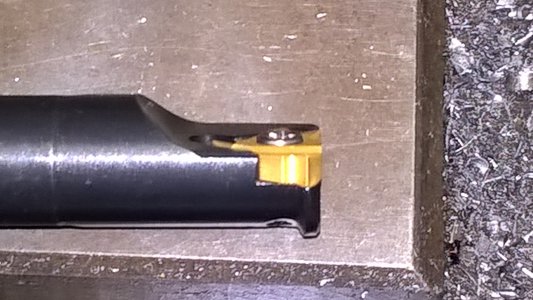

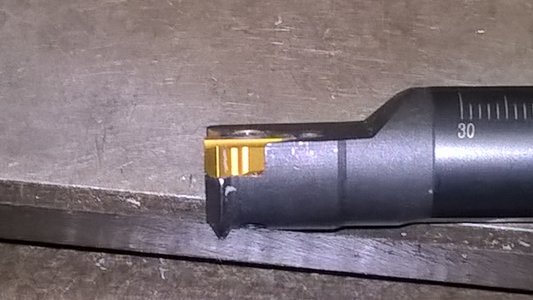

I just bought a left hand inserted threading bar for internal threading from the inside out (backside, reverse rotation). The correct insert is a 16IL-AG60. It appears, with possible exception of the top rake, that insert is the same as a 16ER-AG60. Am I missing something?