- Joined

- Feb 1, 2015

- Messages

- 9,578

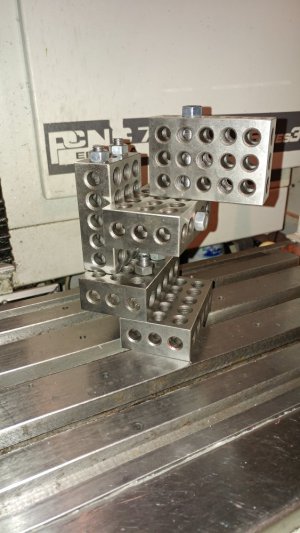

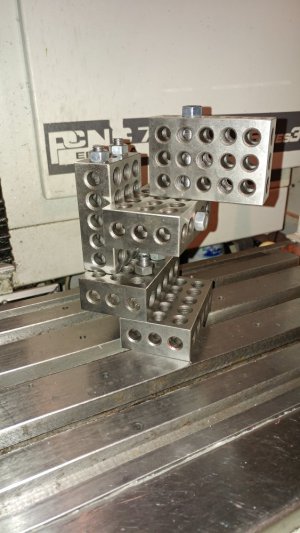

Well, not quite. About a year ago, I purchased five pairs of 1-2-3 blocks to go with the pair I already had. My intent was to use them for machining setups, etc. As mny of us already knew, although the Asian blocks have 3/8"-16 threaded holes on the 2 x 3 face, all the through holes are bored for the the 5/16" tap drill, making them unsuitable for use with 3/8"-16 fasteners.

My idea was to turn down the diameter of a 3/8" bolt to 5/16" to allow them to pass through the blocks and threading the last inch for 5/16"-18. I purchased a selection of 2", 3", and 4" bolts. I used my 5C collet chuck and a 3/8" collet for work holding and turned the hex heads to 3/8" to gain an extra 1/4". For the 2" bolts, I turned the diameter of the shafts to .312", leaving 3/4" of the original 3/.8" thread and threaded about 1" of the opposite end for 5/16"-18. because I had 1-1/2" of stickout, I experienced deflection on the end of the shaft so I chased the threads with a die. Because of the oversized tip thread, I couldn't check the threading progress with a nut but once I got it dialed in, I ran by the numbers on the compound.

The longer bolts were turned to .312" in segments to minimize deflection, again leaving 3/4" of the original thread. I then switched to a 5/16" collet and inserted the bolt through the collet from the back leaving about 1-1/2" exposed for the threading operation. All the threads were chased using a vise for work holding and double nutting the 3/8" thread. This was my first real use of the new electronic lead screw on the 602 and it was a real pleasure not having to mess around with change gears going from turning to threading.

My idea was to turn down the diameter of a 3/8" bolt to 5/16" to allow them to pass through the blocks and threading the last inch for 5/16"-18. I purchased a selection of 2", 3", and 4" bolts. I used my 5C collet chuck and a 3/8" collet for work holding and turned the hex heads to 3/8" to gain an extra 1/4". For the 2" bolts, I turned the diameter of the shafts to .312", leaving 3/4" of the original 3/.8" thread and threaded about 1" of the opposite end for 5/16"-18. because I had 1-1/2" of stickout, I experienced deflection on the end of the shaft so I chased the threads with a die. Because of the oversized tip thread, I couldn't check the threading progress with a nut but once I got it dialed in, I ran by the numbers on the compound.

The longer bolts were turned to .312" in segments to minimize deflection, again leaving 3/4" of the original thread. I then switched to a 5/16" collet and inserted the bolt through the collet from the back leaving about 1-1/2" exposed for the threading operation. All the threads were chased using a vise for work holding and double nutting the 3/8" thread. This was my first real use of the new electronic lead screw on the 602 and it was a real pleasure not having to mess around with change gears going from turning to threading.