- Joined

- Jun 15, 2018

- Messages

- 294

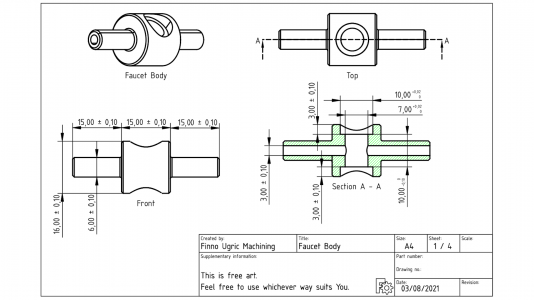

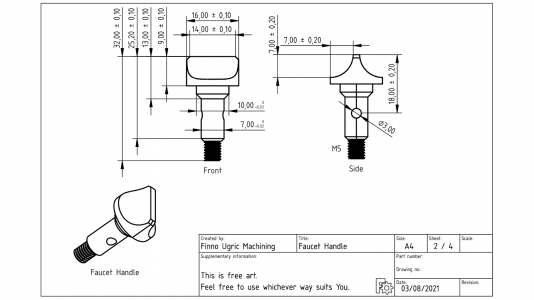

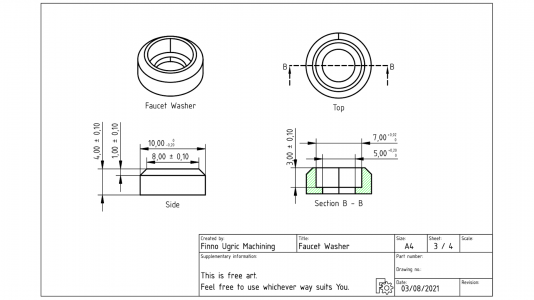

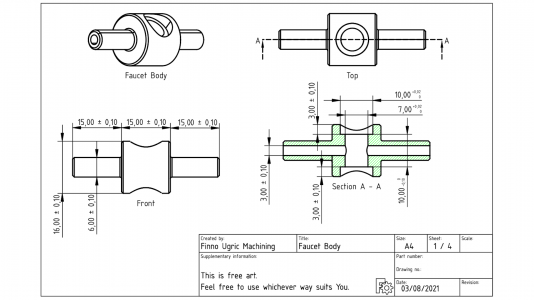

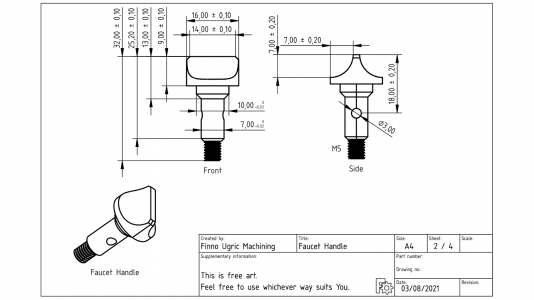

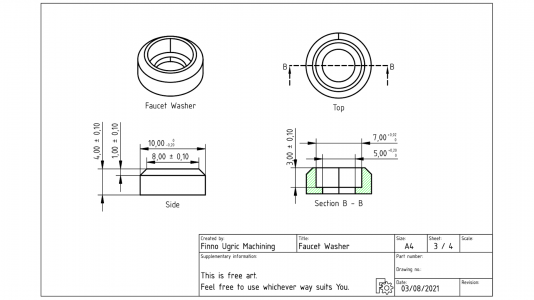

My new lawn mower does not have a faucet. There is a needle valve in the carburettor that is supposed to prevent the gasoline from flooding the carburettor and then running down into the oil pan.

I machine a faucet to prevent this from happening when the lawn mower is not in use.

I made the drawings with the FreeCAD and then I just machine the faucet.

Machining involves some precision turning, milling and drilling.

In this video I am using:

- Weiler Matador SV (1972) Lathe

- Schaublin SV-51 (1955) Milling machine

- Solberga (1975) Drill press

Join the channel:

I upload new videos every other week, usually more frequently.

If You want to see more of my videos, click LIKE & SUBSCRIBE!

You can also subscribe here

I machine a faucet to prevent this from happening when the lawn mower is not in use.

I made the drawings with the FreeCAD and then I just machine the faucet.

Machining involves some precision turning, milling and drilling.

In this video I am using:

- Weiler Matador SV (1972) Lathe

- Schaublin SV-51 (1955) Milling machine

- Solberga (1975) Drill press

Join the channel:

I upload new videos every other week, usually more frequently.

If You want to see more of my videos, click LIKE & SUBSCRIBE!

You can also subscribe here