- Joined

- Mar 2, 2013

- Messages

- 27

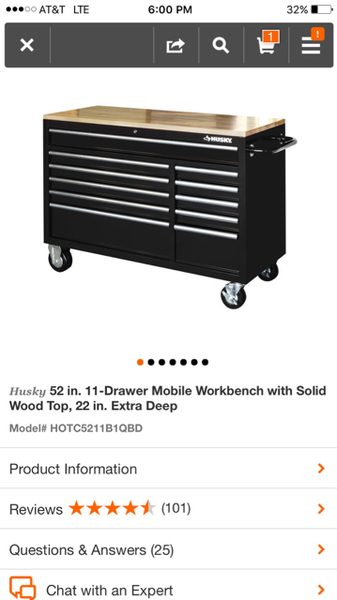

So I recently purchased both a Sherline 2000 8-way mill and a 4400C DRO package lathe. I'm in the process figuring out how I want to set these machines up. I've been thinking about buying something like this and pulling the casters off to make it stationary. This way I would have plenty of tool storage right under the machines. What are you folks using for your bases? Feel free to post up photos please.