-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LEVELING FEET for my new g4003g ? where you get them..........ATT coolidge

- Thread starter dan12

- Start date

- Joined

- Feb 8, 2014

- Messages

- 11,144

You can get these from Enco Tools, McMaster, and Grainger. They are also available from many other vendors.

http://www.use-enco.com/CGI/INPDFF?PMPAGE=501&PARTPG=INLMK3&PMITEM=325-6634

http://www.use-enco.com/CGI/INPDFF?PMPAGE=501&PARTPG=INLMK3&PMITEM=325-6634

Check with use-enco.com. Part no. 325-6629. You can get them for around ten bucks right now with the discount and free shipping. Enter promo codes tue15, then on next screen enter promo code tueups.

Richard

x8.......any cheaper?

- - - Updated - - -

these look any good?

http://www.ebay.com/itm/LEVELING-FE...834?pt=LH_DefaultDomain_0&hash=item4acc45af52

x8.......any cheaper?

- - - Updated - - -

these look any good?

http://www.ebay.com/itm/LEVELING-FE...834?pt=LH_DefaultDomain_0&hash=item4acc45af52

negative on the ebay feet. those are only 1/2" in dia. and would probably be destroyed when you put 1200 lbs on them. if I were you, I would see consider constructing a frame to enlarge the footprint of your stand, firmly bolted to the stand and use only 4 leveling pads attached to the new frame. im designing the same thing for my PM1236, and will be using either 2x2 or 3x3 angle iron, 3/8" thick. Do a search on here and you will get some good ideas.

Richard

seen a few you are talking aboutnegative on the ebay feet. those are only 1/2" in dia. and would probably be destroyed when you put 1200 lbs on them. if I were you, I would see consider constructing a frame to enlarge the footprint of your stand, firmly bolted to the stand and use only 4 leveling pads attached to the new frame. im designing the same thing for my PM1236, and will be using either 2x2 or 3x3 angle iron, 3/8" thick. Do a search on here and you will get some good ideas.

Richard

might do that

thx

- - - Updated - - -

what is hockey?

can you do that in 80-110* weather?:nono::lmao:

T

TOOLMASTER

Forum Guest

Register Today

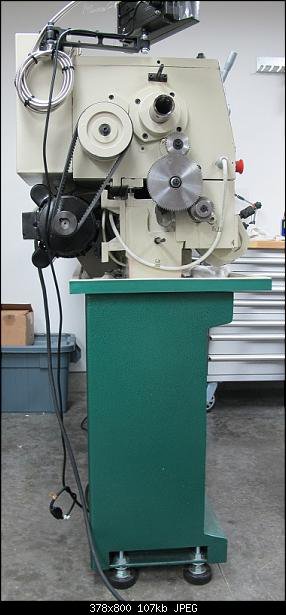

THATS ONE TIPPY LOOKING RIG

Last edited by a moderator:

- Joined

- Dec 18, 2013

- Messages

- 2,012

Dan I made the leveling pads myself out of hockey pucks, 5/8" bolts, jam nuts, and washers. Hockey pucks are great for leveling pads, pretty much indestructible. I have industrial machine leveling pads rated for this weight, the hockey puck pads are much beefier.

Now here's the bad news. First the slot holes for the level pads in the bottom of the lathe stand are so large (about 3/4 inch) the puny 3/8" studs for the industrial leveling pads for this weight are way too small. You would have to stack a bunch of fender washers together otherwise they would just bend into the slot as you tighten them hence the reason I went with 5/8" bolts. You could go with larger industrial leveling pads but that gets very expensive fast when you start spending $30-$60 for each pad. There's more, the lathe stand is WAY too tall to begin with and even using thin jam nuts you will add another 2" in height to an already too tall stand. My brother and I took some measurements (he's been a machinist for 25 years) we figure the lathe stand needs to be cut down 5-6 inches in height vs on the pads its on. Also as you can see in the pics the pads are located well inside the stand which makes it tippy front to back. Its not going to tip over in use most likely but I have been in a minor 5.0 earthquake and could see it tipping right over the way its setup now.

So honestly I would not use leveling pads at all, I would set it right on the floor and shim it level. My garage floor slopes substantially but I only have about 1/4" different in height between the rear and front leveling pads as pictured. I'm going to remove these pads from my lathe soon and shim. I may put the rear down on a thin rubber pad then shim the front to level. I'm not too bad side to side level wise so I think I'll be okay there.

That's my 2 cents worth.

Now here's the bad news. First the slot holes for the level pads in the bottom of the lathe stand are so large (about 3/4 inch) the puny 3/8" studs for the industrial leveling pads for this weight are way too small. You would have to stack a bunch of fender washers together otherwise they would just bend into the slot as you tighten them hence the reason I went with 5/8" bolts. You could go with larger industrial leveling pads but that gets very expensive fast when you start spending $30-$60 for each pad. There's more, the lathe stand is WAY too tall to begin with and even using thin jam nuts you will add another 2" in height to an already too tall stand. My brother and I took some measurements (he's been a machinist for 25 years) we figure the lathe stand needs to be cut down 5-6 inches in height vs on the pads its on. Also as you can see in the pics the pads are located well inside the stand which makes it tippy front to back. Its not going to tip over in use most likely but I have been in a minor 5.0 earthquake and could see it tipping right over the way its setup now.

So honestly I would not use leveling pads at all, I would set it right on the floor and shim it level. My garage floor slopes substantially but I only have about 1/4" different in height between the rear and front leveling pads as pictured. I'm going to remove these pads from my lathe soon and shim. I may put the rear down on a thin rubber pad then shim the front to level. I'm not too bad side to side level wise so I think I'll be okay there.

That's my 2 cents worth.

Dan I made the leveling pads myself out of hockey pucks, 5/8" bolts, jam nuts, and washers. Hockey pucks are great for leveling pads, pretty much indestructible. I have industrial machine leveling pads rated for this weight, the hockey puck pads are much beefier.

Now here's the bad news. First the slot holes for the level pads in the bottom of the lathe stand are so large (about 3/4 inch) the puny 3/8" studs for the industrial leveling pads for this weight are way too small. You would have to stack a bunch of fender washers together otherwise they would just bend into the slot as you tighten them hence the reason I went with 5/8" bolts. You could go with larger industrial leveling pads but that gets very expensive fast when you start spending $30-$60 for each pad. There's more, the lathe stand is WAY too tall to begin with and even using thin jam nuts you will add another 2" in height to an already too tall stand. My brother and I took some measurements (he's been a machinist for 25 years) we figure the lathe stand needs to be cut down 5-6 inches in height vs on the pads its on. Also as you can see in the pics the pads are located well inside the stand which makes it tippy front to back. Its not going to tip over in use most likely but I have been in a minor 5.0 earthquake and could see it tipping right over the way its setup now.

So honestly I would not use leveling pads at all, I would set it right on the floor and shim it level. My garage floor slopes substantially but I only have about 1/4" different in height between the rear and front leveling pads as pictured. I'm going to remove these pads from my lathe soon and shim. I may put the rear down on a thin rubber pad then shim the front to level. I'm not too bad side to side level wise so I think I'll be okay there.

That's my 2 cents worth.

good idea

was thinking of that

it's cheap=free,lol

& I can do that now,no waiting on pads or making my own

I have welders,etc to do that,just not much free time,like most people

thx again

might weld on angle later and use bolts top level if needed with steel & rubber blocks I can make

seen someone on here do it