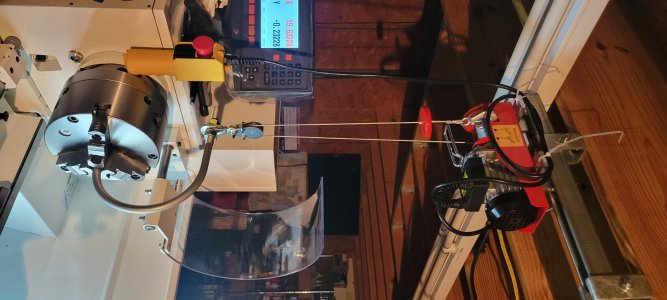

Here you go Mal. I was in the shop and took a couple of pics. The hook is and easy build. About 3/4” round bar for clamping in the jaws and 1/2”x1/2” square coming off at 30 degrees....welded and bent. Here’s a couple of pics. I can turn the chuck either way once it’s supported by a hook of the come-along or winch. Going from horizontal to vertical...It’s easy.

just make sure the jaws are tight before you flip it...because when removing a jaw from the lathe, the jaws don’t have to be super tight. But when flipped.... Jaws better be tight or it’s going fall out of hook.

just make sure the jaws are tight before you flip it...because when removing a jaw from the lathe, the jaws don’t have to be super tight. But when flipped.... Jaws better be tight or it’s going fall out of hook.