- Joined

- Oct 14, 2014

- Messages

- 1,967

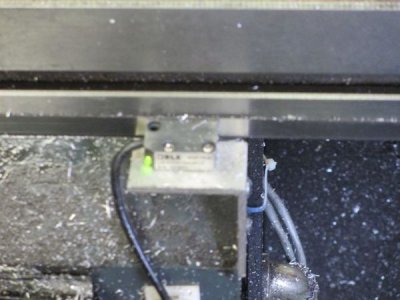

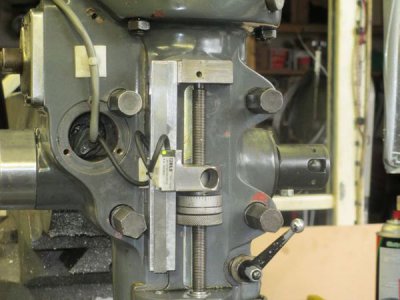

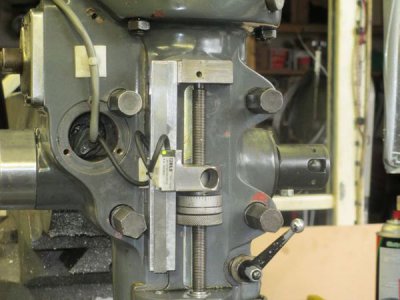

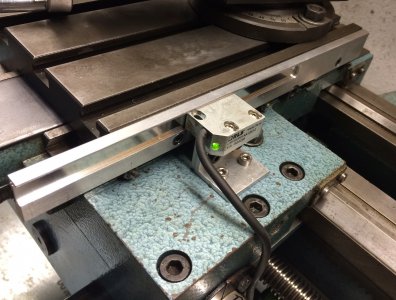

I'd like to try adding a linear encoder to my CNC control. The control needs quadrature differential input at 5 volts.

Anyone know of digital scales that conform to this spec?

So far my only option seems to make my own scale by purchasing a linear encoder kit from US Digital

http://www.usdigital.com/products/encoders/incremental/linear/LIN

Karl

Anyone know of digital scales that conform to this spec?

So far my only option seems to make my own scale by purchasing a linear encoder kit from US Digital

http://www.usdigital.com/products/encoders/incremental/linear/LIN

Karl