- Joined

- May 26, 2015

- Messages

- 747

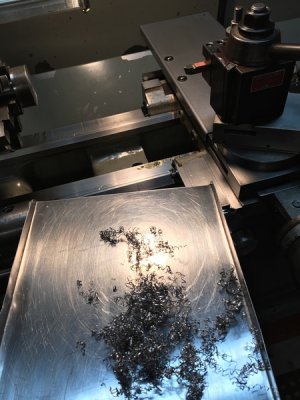

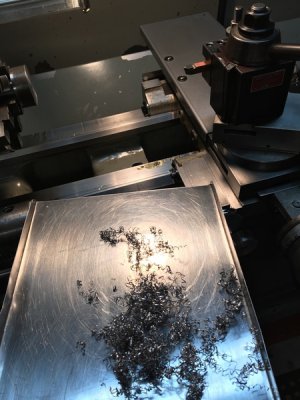

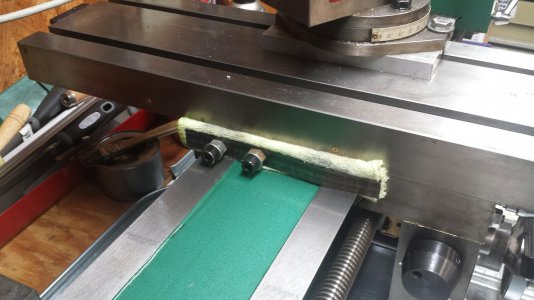

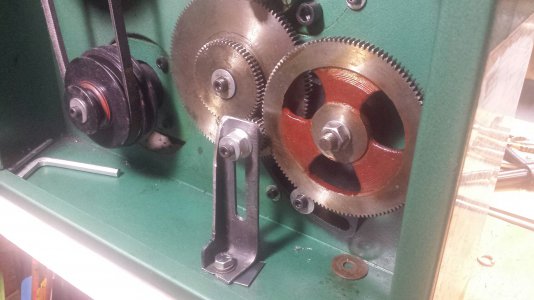

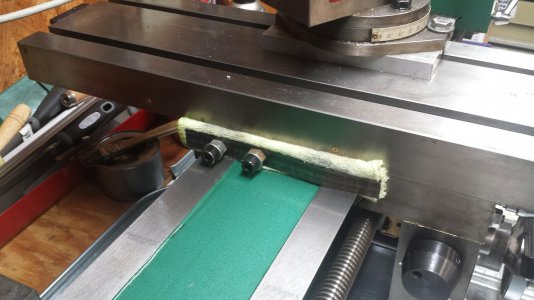

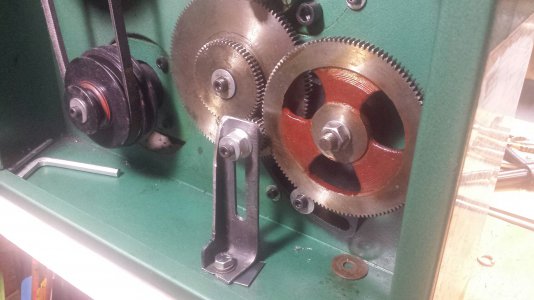

After recently starting to play around with my G9729 lathe I new there were some simple improvements I could do. The carriage shuttle handle was too small, no chip cover for ways and wanted a cheapo QCTP grinder to do grinding and cutting. (Saw the QCTP grinder on YouTube) I also made a ways oiler/cleaner. The reverse lead screw project is still a work in progress.

. Vinyl maybe better donno, just the breeze from the chuck revolving lifted it till it snagged a jaw and tore loose. I jumped back in time but it could of Been a lot worse.

. Vinyl maybe better donno, just the breeze from the chuck revolving lifted it till it snagged a jaw and tore loose. I jumped back in time but it could of Been a lot worse.