- Joined

- Aug 3, 2017

- Messages

- 2,437

Hi all-

I purchased a 10" Montgomery Ward lathe, which was made by Logan. It is an early 1950s from everything I can tell. I had the buyer do a test-cut to show it worked, but it was with aluminum.

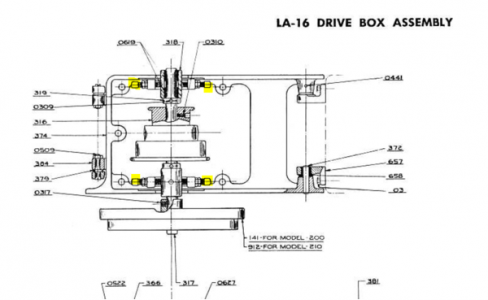

I moved it with a buddy, but at one point attempted to remove the cloth flat belt by disassembling the drive-spindle. I loosened the two shaft collar allen screws, and tried to tap it out. It was pretty tight, and I only got it to move about 3/4" before giving up and reassembling it. I didn't notice before hand how difficult it was to move that spindle, but it is not very 'free wheeling' at the moment. I can move it by hand, but it stops immediately.

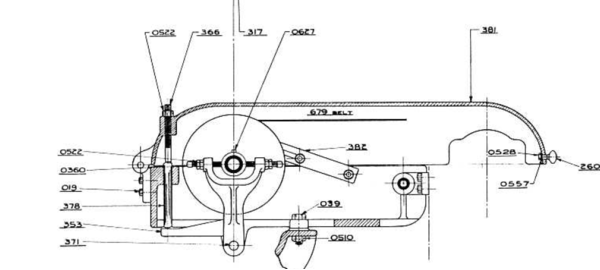

Currently, there is a 1/3HP powerkraft motor on it that smoked when I had it on the small motor pulley to the big-wheel, even with the flat-belt detensioned. When on the bigger of the two pulleys and on the smaller flat wheel, it seems to run the lathe fine, however it stalls pretty easy.

I have a spare 1HP motor that looks like it'll fit that I was going to install, but before doing that I wanted to make sure that I hadn't messed up the spindle!

Thanks!

I purchased a 10" Montgomery Ward lathe, which was made by Logan. It is an early 1950s from everything I can tell. I had the buyer do a test-cut to show it worked, but it was with aluminum.

I moved it with a buddy, but at one point attempted to remove the cloth flat belt by disassembling the drive-spindle. I loosened the two shaft collar allen screws, and tried to tap it out. It was pretty tight, and I only got it to move about 3/4" before giving up and reassembling it. I didn't notice before hand how difficult it was to move that spindle, but it is not very 'free wheeling' at the moment. I can move it by hand, but it stops immediately.

Currently, there is a 1/3HP powerkraft motor on it that smoked when I had it on the small motor pulley to the big-wheel, even with the flat-belt detensioned. When on the bigger of the two pulleys and on the smaller flat wheel, it seems to run the lathe fine, however it stalls pretty easy.

I have a spare 1HP motor that looks like it'll fit that I was going to install, but before doing that I wanted to make sure that I hadn't messed up the spindle!

Thanks!