Peoples eyesight must have been very good in the '40s. That's the only theory that can explain the tiny dials on the lathes and mills of that era.

I finally designed a setup to make new ones for my Logan. It took about a year to design and make the fixture and less than half an hour to actually scribe the dials.

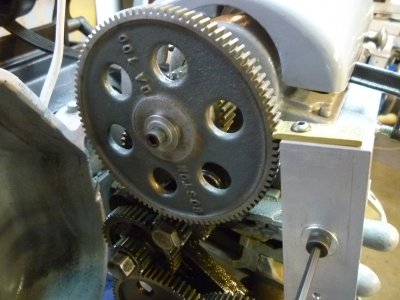

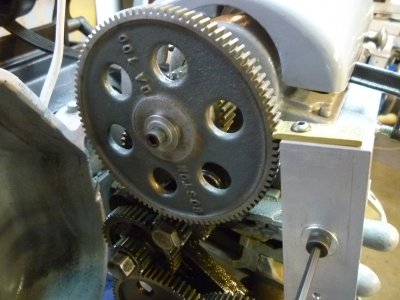

I made an arbor to mount a 100 tooth gear on the outboard end of my lathe headstock. Using available material I made an index lock with a brass finger to lock the gear in position. I made the brass finger to be softer than the gear to minimize wear on the gear.

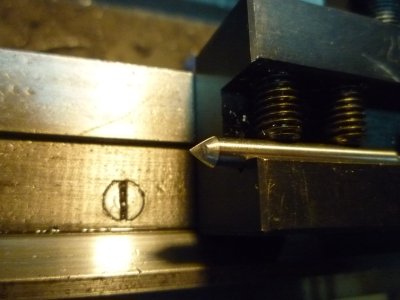

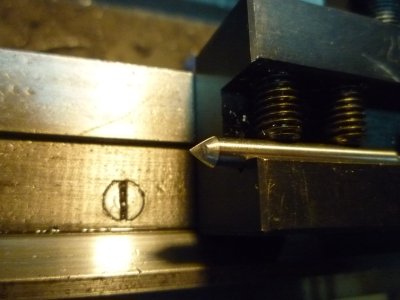

The scriber is a broken 3/16 endmill ground to a 60° angle in a drill on a belt sander. I tried scribing with a full round scribe and one with a flat ground in the tip to make it more a cutting tool. I settled on the cutting tool version. I mount it in a boring bar tool holder. This scribe is easy to make, easy to sharpen and duplicate.

I found that the best scribed lines occurred with a scribe depth of .004. Deeper and the lines got mushy. Less and they just weren't distinct enough.

On my dials I set the carriage stop to make the small marks and cut 100 of them. I reset the stop to cut the .005 lines and simply marked over the existing short marks. Same procedure for the .010 lines. The system is so accurate and repeatable that you can re-cut existing lines with no "shadows".

I now have to figure out how to make a jig to hold the stamps to put the markings on the dials. Any assistance with that, including photos will be much appreciated.

I finally designed a setup to make new ones for my Logan. It took about a year to design and make the fixture and less than half an hour to actually scribe the dials.

I made an arbor to mount a 100 tooth gear on the outboard end of my lathe headstock. Using available material I made an index lock with a brass finger to lock the gear in position. I made the brass finger to be softer than the gear to minimize wear on the gear.

The scriber is a broken 3/16 endmill ground to a 60° angle in a drill on a belt sander. I tried scribing with a full round scribe and one with a flat ground in the tip to make it more a cutting tool. I settled on the cutting tool version. I mount it in a boring bar tool holder. This scribe is easy to make, easy to sharpen and duplicate.

I found that the best scribed lines occurred with a scribe depth of .004. Deeper and the lines got mushy. Less and they just weren't distinct enough.

On my dials I set the carriage stop to make the small marks and cut 100 of them. I reset the stop to cut the .005 lines and simply marked over the existing short marks. Same procedure for the .010 lines. The system is so accurate and repeatable that you can re-cut existing lines with no "shadows".

I now have to figure out how to make a jig to hold the stamps to put the markings on the dials. Any assistance with that, including photos will be much appreciated.