HiCap239, MBfrontier was not talking about a twisted bed, he was describing how to check for a worn bed. With bed wear, which is usually mostly near the chuck, the ways become worn downwards, making the distance from the top of the ways to the carriage clamping surface below the ways less. If you tighten the carriage while it is near the chuck and then loosen it just enough that it moves with slight resistance, and then move the carriage to the right where there is typically less wear, you can see if the carriage gets harder to move as it goes to the right, indicating wear near the chuck. It is a quick and dirty test, and does not quantify the extent of the wear very well, but at least it gives you an idea of what is going on. Looking at the ways visually will not really show much beyond extreme wear and physical damage, (dings, etc.)

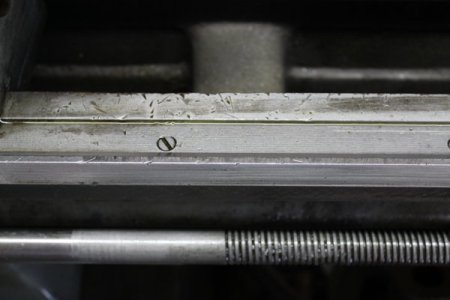

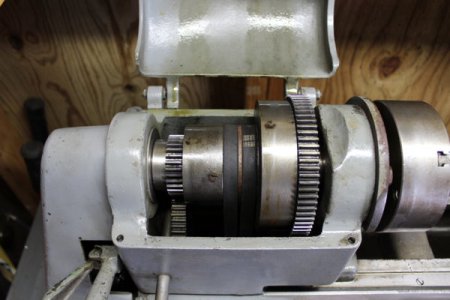

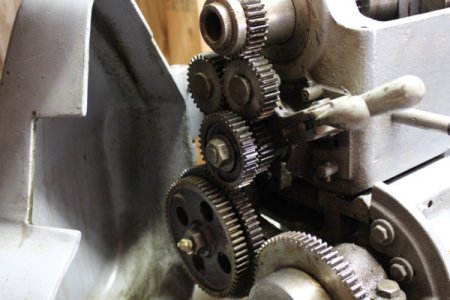

Thanks for the info, I was wondering about that. I did just what was stated above. I just did not know what It was called. I also stuck a straight bar against the front part of the prism way by the chuck out 10 inches and put a flashlight angled down angled down and against the bar and inner flat way. You can see light which gives a somewhat more accurate means of measure. When I did the twisted bed test it did indeed get harder to turn as the carriage approached the tail stock area. However it did not get so tight that I could not turn it. I snugged it up until it was not to easy to crank in front of the chuck. I ran it back and forth several times, next I ran it up within 3 inches of the chuck and grabbed the back of the carriage and grabbed the bottom of the Apron and tried to life it. There had to be some play, but I really could not detect it. I did this in various other places then went back to the front section and still could not tell any discernible difference. Unfortunately there is no steady rest, or a 4 jaw chuck for that matter not much in the way of tooling. His money is in measuring equipment. Lots of Starrett stuff, along with Brown & Sharp. Gears checked out A ok all the way around. He had the thing dripping with oil when I got there. He had it for 9 years and bought it from an old timer he knew that was familiar with lathes. I also checked the change gear box gear sets running and not. All were good to go. One issue I need information on is the machine would drop out of gear when running sometimes. The (Excuse my ignorance on the proper name of this) lever on the left of the gearhead assembly that engages the gears with the black knob (see pictures) up above the quick gear change box seems to have a lot of slop in it. I felt underneath it and it feels like there is a keyway slot of sorts. I have no idea how "tight" this should be but it seems to have what I would consider a lot of side to side play in it. I can see it rides on top of something possibly a shaft with a gear on it inside of the upper gear assembly. When it drops out of gear the seller shut down the unit then pulled while wiggling the bar/knob assembly back out and it would lift the gear back up into place. He said it must need adjusting and he did not know anything about it so he did not want to mess with it. Any info would greatly be appreciated. He was honest and let me take my time and all the pictures I wanted of it and run it as long as I wanted. Here re some pictures with my good camera. I told him there was no way I was going to trade him what I had for that even with the tooling. I did offer up a lesser trade that I felt would be fair for both of us and that he could keep the measuring instruments. He said he was good with that, but he wanted to wait since he had spoken with a gentleman from the other coast and promised he could come and look at the lathe this Wednesday. He said he had a better trade, so the deal was left for him to consider until the other guy looks at it. Looks like I will not know anything until Wednesday or later on whether or not I will get the lathe. Let me know if anyone sees anything in the pictures that I have not have described and may have missed. I also pushed and pulled the chuck and there was no movement back and forth so it was good also. Thanks guys and enjoy the pictures.