- Joined

- Nov 17, 2017

- Messages

- 1,525

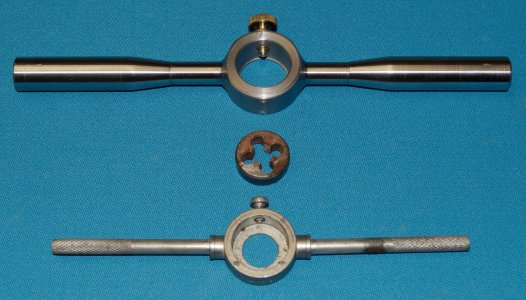

A few days ago I was standing around in my shop bored partially because my McMaster Carr shipment had not arrived, and partially because I had just finished cleaning and I still needed something to do for a few hours. As I pondered my next move, I noticed a block of steel lying in the corner of my stash bins. It came to me that I never liked the Die Wrench that can in my tap and die kit from about 20 years ago. In that block of steel I saw a new, beefier, weighter, and nicer die wrench.

So, I got to work and produced this::

Witness that it is of the same scale, but simply beefier, and ample enough that I may never need another die wrench for as long as I machine.....

It was all machined on centers (Both longitudinally and vertically). It took about 11 hours, 4 of which were simply figuring out how to hold the part on the rotary table solidly enough that the machining forces were not moving the piece being machined.

Anyway It came out great, and has a nice balanced feel about it. I learned a lot about how to setup parts using dial indicators, and concentricity indicators.

So, I got to work and produced this::

Witness that it is of the same scale, but simply beefier, and ample enough that I may never need another die wrench for as long as I machine.....

It was all machined on centers (Both longitudinally and vertically). It took about 11 hours, 4 of which were simply figuring out how to hold the part on the rotary table solidly enough that the machining forces were not moving the piece being machined.

Anyway It came out great, and has a nice balanced feel about it. I learned a lot about how to setup parts using dial indicators, and concentricity indicators.