-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for a suggestion for gear oil for the headstock of a lathe...

- Thread starter Dabbler

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,625

ISO32 Mobil DTE light

it's the OEM equivalent fluid

it's the OEM equivalent fluid

- Joined

- Sep 5, 2014

- Messages

- 428

Lucky you , may I say I'm a little green, chuckle . There are all sort of special recommendations . I looked up the crisscross for oil wt and I found diff oil matches, get some 80-140 syn. You can't get better oil. I use Lucas. It easy to find as well. It doesn't eat brass. Well, you can buy better, but you have to buy a drum and it would cost as much as your lathe.

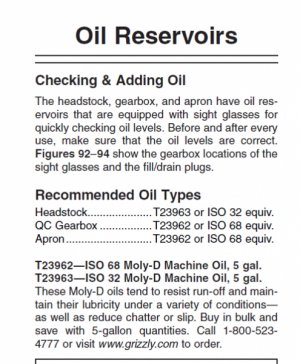

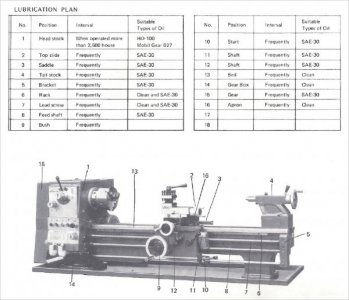

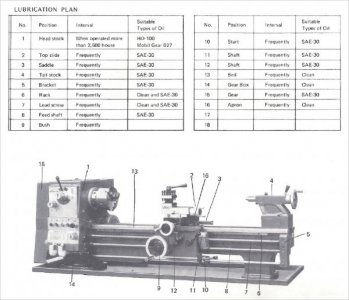

Here is what my manual says ('97 vintage 14x40). I would have to check but I believe this oil is similar to what I got at the time for the headstock gearbox from CDN Tire. The sight glass looks very clean but probably time for a flush for me too.

I also use the same oil that goes in from the side .......riiiight by that bank of electrical switches & buttons...... & flows into a felt padded tray right about where the #14 points to. That then somewhat distributes over the change gears below. Much thinner & it drips through too fast. Much thicker & it kind of hangs up in the felt.Your lathe might be newer gen, but anyway maybe helps.

I also use the same oil that goes in from the side .......riiiight by that bank of electrical switches & buttons...... & flows into a felt padded tray right about where the #14 points to. That then somewhat distributes over the change gears below. Much thinner & it drips through too fast. Much thicker & it kind of hangs up in the felt.Your lathe might be newer gen, but anyway maybe helps.

- Joined

- Jun 12, 2014

- Messages

- 4,808

Agree with Ulma Doctor, ISO32 gear head oil is what is most commonly used and reasonably priced. Multi-viscosity oils used in cars and differentials are not recommended, and based on different operating temperatures ranges. The 80-140 (ISO 100-460) syn is way more expensive and significantly more viscous then ISO32, this will lead to increased friction and possible bearing failure due to lack of splash lubrication getting to the top of the head and into the lubrication channels to the bearings. Just about every gear head lathe specifies ISO32 in the headstock and ISO68 in the gearbox, I do not see any reason to deviate from this unless you live in the Arctic Circle or the tropics. No need for anything fancy for this application. Oils for differentials like the Amsoil have friction modifiers along with other agents specific to limited slip differentials that increase the friction. They have no place in gearhead lathes. Synthetic oils should not be used on new machinery until they are broken in, after that point they may have some application if you want to have extended oil intervals. You still should use a straight weight per the manufactures recommendation.

I have used Amsoil Hypoid Marine (SAE 75W/90, SAE 30 or ISO 100) synthetic oil in gear head mills that specify ISO100 oil with good results, also synthetic oils are used in other machinery like compressors that give much longer oil change intervals. You still have issues of condensation and contamination which may limit the length of the oil change intervals.

https://www.engineeringtoolbox.com/iso-vg-grade-d_1206.html

Added info: Most oils will indicate if they can be used with yellow metals (Copper strip corrosion test), not all EP additives attack yellow metals, and the newer sulfur based versions are inert (inactive) at room temperature and are activated with heat. So although the Amsoil Hypoid Marine oil mentioned above has EP additives it is safe to use with yellow metals, this was also confirmed with Amsoil's technical department. You should not need EP additives with standard straight cut gears, but almost all gear oils have some form of anti-wear additives.

https://www.machinerylubrication.com/Read/28958/ep-additives-effects

I have used Amsoil Hypoid Marine (SAE 75W/90, SAE 30 or ISO 100) synthetic oil in gear head mills that specify ISO100 oil with good results, also synthetic oils are used in other machinery like compressors that give much longer oil change intervals. You still have issues of condensation and contamination which may limit the length of the oil change intervals.

https://www.engineeringtoolbox.com/iso-vg-grade-d_1206.html

Added info: Most oils will indicate if they can be used with yellow metals (Copper strip corrosion test), not all EP additives attack yellow metals, and the newer sulfur based versions are inert (inactive) at room temperature and are activated with heat. So although the Amsoil Hypoid Marine oil mentioned above has EP additives it is safe to use with yellow metals, this was also confirmed with Amsoil's technical department. You should not need EP additives with standard straight cut gears, but almost all gear oils have some form of anti-wear additives.

https://www.machinerylubrication.com/Read/28958/ep-additives-effects

Last edited:

- Joined

- Jul 2, 2014

- Messages

- 7,594

Extreme pressure (EP) gear oils will eat yellow metals (brass, copper, etc.) Lathe gearboxes often have brass or bronze bushings, clutches, and washers. Do not use EP oils with yellow metals!Here is what my manual says ('97 vintage 14x40). I would have to check but I believe this oil is similar to what I got at the time for the headstock gearbox from CDN Tire. The sight glass looks very clean but probably time for a flush for me too.

I also use the same oil that goes in from the side .......riiiight by that bank of electrical switches & buttons...... & flows into a felt padded tray right about where the #14 points to. That then somewhat distributes over the change gears below. Much thinner & it drips through too fast. Much thicker & it kind of hangs up in the felt.Your lathe might be newer gen, but anyway maybe helps.

- Joined

- Jul 2, 2014

- Messages

- 7,594

If it is an Asian lathe use AW32 hydraulic oil. It is the correct viscosity, and AW32 meets the specs easily and costs much less than specialty oils. AW stands for "anti wear', it contains anti wear additives.I just acquired a 1440 gear head lathe, and I want to replace the oil in the headstock. What do you use and why?

- Joined

- Apr 28, 2014

- Messages

- 3,590

- Joined

- Apr 28, 2014

- Messages

- 3,590

As the saying goes, "Learn something new each and every day." This one is very pertinent.Extreme pressure (EP) gear oils will eat yellow metals (brass, copper, etc.) Lathe gearboxes often have brass or bronze bushings, clutches, and washers. Do not use EP oils with yellow metals!

Extreme pressure (EP) gear oils will eat yellow metals (brass, copper, etc.) Lathe gearboxes often have brass or bronze bushings, clutches, and washers. Do not use EP oils with yellow metals!

OK, that's real good to know. I'll confirm what I have, maybe its just the weight I remember. I feel like I've heard this 'eats brass' before & someone else said - yes, but are likely found within many kinds of gearboxes or no - only if it contains sulfur...

What would be a typical applications of an EP oil? My first random Google pick. Fancy that, I swear I didn't weight the dice. It says EP Gear Oil is non-corrosive to brass, bronze, steel or other alloys. https://www.lsc-online.com/industrial-ep-gear-oil/