- Joined

- Dec 25, 2011

- Messages

- 10,511

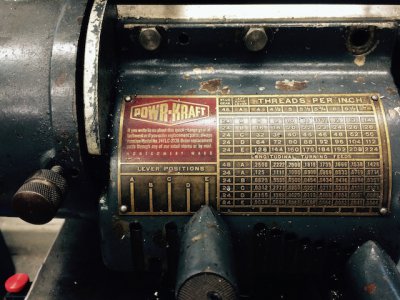

Putting a larger pulley on the motor would speed the lathe up, not slow it down. To achieve the original spindle speeds with a 3450 RPM motor, the smaller dia. motor pulley would have to be about 1-1/8" dia. Too small for a 3L or 4L belt.