- Joined

- Sep 15, 2017

- Messages

- 321

Hello

Looking for help on basic ideas for suitable vfd to fit to my new second hand boxford aud.Currently its 3 phase were it is but plan to move it in the future to were i only have 240volt single phase .The lathe still has original wiring and switches in it .

The safety switches for backgear lockout .cabinate door. gear train cover and estop run of 110volt through a magnetic contactor .

I would like to still keep all these switches and safety devices in use when i change to VFD i would also like to utalise original forward off reverse switch .

What VFD would allow me to utalise all these and suit my electric motor .

I would also like to fit a foot pedal that you could depress when threading at very low speed obviuosly due to scew on chuck that would stop the motor and also brake at the same time .

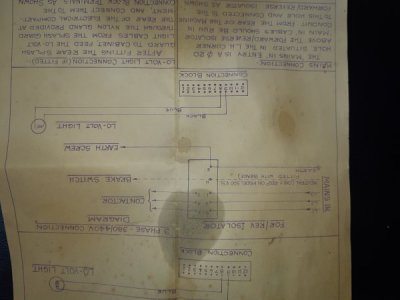

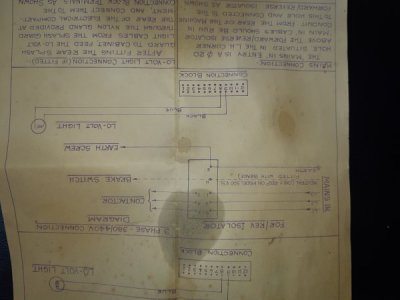

I am far from being an electricial but would appreciate if i could get advice on a vfd that would cover this and ideas on how to wire it all up to work have attached best picture of motor plate and a basic wiring diagram that originally came with lathe with manual .it only shows basic motor wiring .

Looking for help on basic ideas for suitable vfd to fit to my new second hand boxford aud.Currently its 3 phase were it is but plan to move it in the future to were i only have 240volt single phase .The lathe still has original wiring and switches in it .

The safety switches for backgear lockout .cabinate door. gear train cover and estop run of 110volt through a magnetic contactor .

I would like to still keep all these switches and safety devices in use when i change to VFD i would also like to utalise original forward off reverse switch .

What VFD would allow me to utalise all these and suit my electric motor .

I would also like to fit a foot pedal that you could depress when threading at very low speed obviuosly due to scew on chuck that would stop the motor and also brake at the same time .

I am far from being an electricial but would appreciate if i could get advice on a vfd that would cover this and ideas on how to wire it all up to work have attached best picture of motor plate and a basic wiring diagram that originally came with lathe with manual .it only shows basic motor wiring .