- Joined

- Jun 10, 2019

- Messages

- 532

I picked up an old Rockwell 23-505 diamond tool grinder and had some general questions about wheel types. I picked this up for grinding lathe HSS and Carbide grinding. In both cases I'm expecting minor clean up and not bulk grinding (I have a regular grinder for that). My general understanding has been:

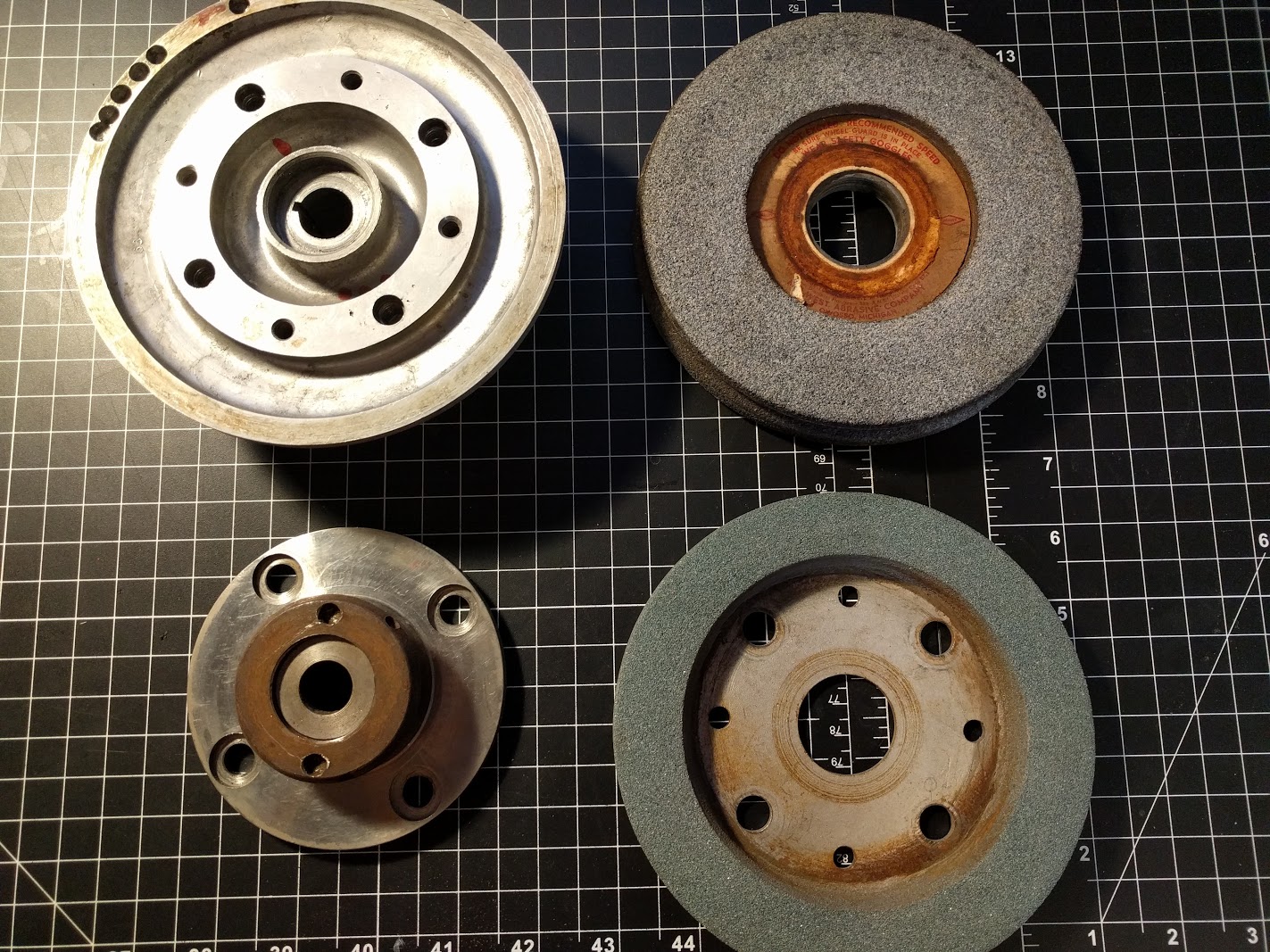

What I'd like to know is what sort of wheel styles (types) are preferable and grits would typically be used? I was thinking generally medium or fine would be better suited for what I'm looking to use this for, but not sure. I tried looking up the wheels which came with the grinder to get an idea, but can't find either. I attached a pic of one of the grinder's OEM flange wheels, an adapter for solid abrasive wheels and the 2 grinding wheels it came with.

- Aluminum Oxide for HSS

- Silicone Carbide for HSS (finer grinding) and Carbide

- Diamond for Carbide

What I'd like to know is what sort of wheel styles (types) are preferable and grits would typically be used? I was thinking generally medium or fine would be better suited for what I'm looking to use this for, but not sure. I tried looking up the wheels which came with the grinder to get an idea, but can't find either. I attached a pic of one of the grinder's OEM flange wheels, an adapter for solid abrasive wheels and the 2 grinding wheels it came with.

The green wheel is a Norton 39C100 H8VK. I can't find this exact wheel on their site, but this looks very close: p/n 66252838330 (link). 100 grit. They are billed as a 4" arbor. The center hole is 1-1/4", but the ID of the grinding material itself is 4". So would I normally look up using the latter? Is there a general name for this style with the metal backing plate and 8-hole pattern? I was going to say "cupped", but I thought cupped wheels were much deeper than this type and made entirely of grinding material (no metal back).

The aluminum oxide wheel says 7x1x1-1/4, but actually measures 6" in diameter. Why the 1" difference? Mid-west abrasive company, P/N appears to be SFA-6019-VJC (the "1" is hard to read and could be an L? and there could be a space between the 60 and the 1/L). I can't find this part number anywhere and it seems they have been long out of business. Pretty sure its a 60 grit. Is there a general name for this type of wheel which is solid abrasive with the recessed center for face grinding? The edge of this wheel has some serious profile ground into it. I was debating on scrapping it instead of trying to true it. Still worth hanging onto?