I'll try & describe a situation I keep running into with words, but if that doesn't work I'll take a pic. Basically I am turning parts that have an extending boss off the end. They need to be accurate but I'm having a tough time getting conventional micrometer anvils over the boss diameter because the part of the mic where anvils come out of actually bump up against the material behind it. Even now I can only get half the anvil on so always conscious of proper contact & perpendicular to the surface. I can get conventional caliper jaws across it because the jaws are thin & flat, but they aren't really that great for accuracy compared to a mike. So to put numbers to a part, say the base stock diameter is 3" with a 1" diameter boss extending of this, but only sticks out 0.100".

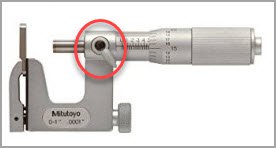

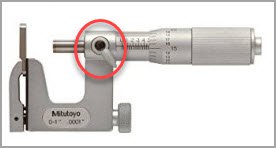

I was thinking this style with the extended anvil might be better. But I think I'll run into the same issue where the anvil area material conflicts. https://www.itm.com/product/mitutoyo-117-107-micrometer-unimike-0-1in-0001in

I used my 2" mike with a gage block in between. It somewhat worked because the fixed end is smaller. But its fiddly & error prone. There has to be a better way?

I was thinking this style with the extended anvil might be better. But I think I'll run into the same issue where the anvil area material conflicts. https://www.itm.com/product/mitutoyo-117-107-micrometer-unimike-0-1in-0001in

I used my 2" mike with a gage block in between. It somewhat worked because the fixed end is smaller. But its fiddly & error prone. There has to be a better way?