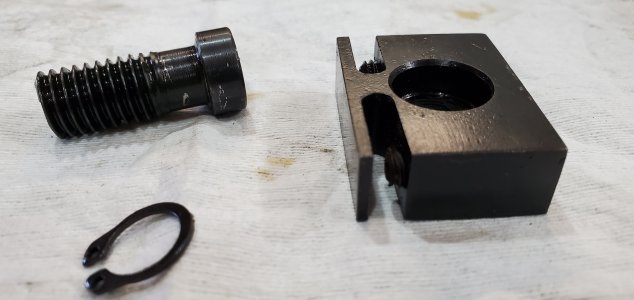

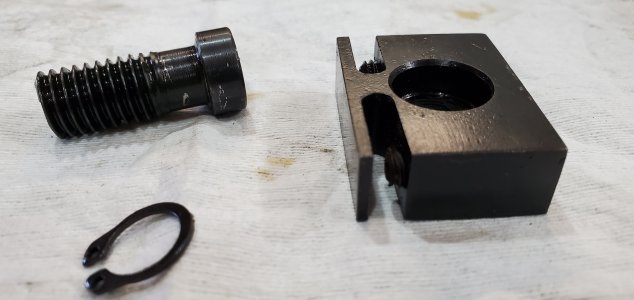

Just lurking around on Blondehacks YouTube She made a couple of clamping blocks for her her small bench top mill. I thought it was a great idea and a fun little project. So I made 6 of them . Their mild steel, 1/2 thick x 1/1/2 long x 1 1/4 width 2 1/4 20 set screws and a modified 1/2 x 13 socket head cap screw, and a snap ring to capture the cap screw. The flexure slot is 3/16. I blackened them with Casswell's cold bluing. Also the side that sits on the mill table has been under cut by .010 for clearance. You can see that in pic 3

Thank You!!!!

Thank You!!!!