Jan,

You didn't say what model lathe you have but I have a 3996 that uses all of those same parts. I never noticed it but my cross feed screw assembly does not have an M6-255 either. And I have never had any problem with the 10D-262 Special Ball Crank Nut coming loose.

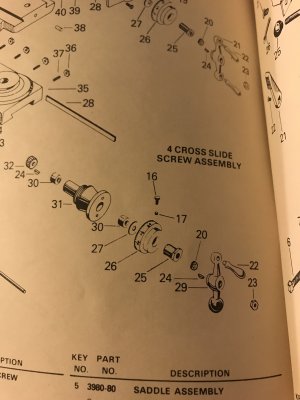

The proper way to tighten the 10D-262 Nut is to hold the 049-089 Bushing with a tappet wrench (thin pattern open end) without turning it and tighten the 10D-262 Nut with a 6-point socket or box end wrench.

If after doing that, the crank is too difficult to turn or the backlash is excessive, first crank the 537-041 Carriage Slide Nut off the end of the cross feed screw and push the cross slide away another quarter inch. Note how much effort it takes to turn the crank. There should be just a slight drag. If you spin the crank, it should stop almost immediately but not be difficult to turn. If not, hold the 049-089 Bushing with the tappet wrench and loosen the 10D-262 Nut. Loosen or tighten the 049-089 Bushing one flat, hold it with the tappet wrench without turning it and re-tighten the 10D-262. If that makes the crank too hard to turn, back off the 049-089 Bushing one-half a flat, re-tighten the 10D-262 and try it again. When satisfied with the feel of the crank, pull the cross slide back towards you while turning the crank CCW. A after the screw picks up the threads in the nut, crank the cross slide back to where it normally runs and check the back lash with the dial. With a 37 year old nut, I was getting about .008" of backlash. With a new nut, that dropped to about .002".