- Joined

- Oct 8, 2015

- Messages

- 71

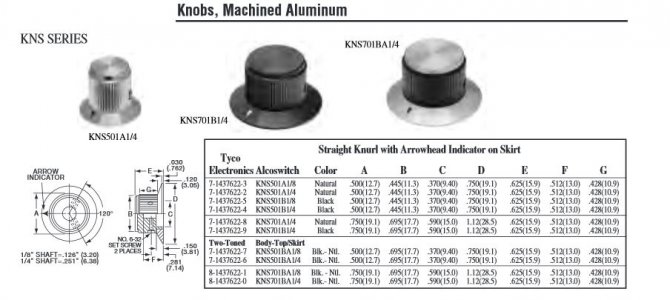

Think "eighties hi-fi knobs".

These dials are usually metalized plastic and have the shaft pocket splined or with a half-moon section to mate with the switch shaft. Since they are cast as-is if plastic or forged with a die if metal in production, it's no problem if you have that equipment. But how would you manually machine the pocket from a blank while preserving your tooth enamel?

The splines I can invision should be straightforward with an indexing head or rotary table and a shaping bit, but what about the half-moon?

Thanks!

These dials are usually metalized plastic and have the shaft pocket splined or with a half-moon section to mate with the switch shaft. Since they are cast as-is if plastic or forged with a die if metal in production, it's no problem if you have that equipment. But how would you manually machine the pocket from a blank while preserving your tooth enamel?

The splines I can invision should be straightforward with an indexing head or rotary table and a shaping bit, but what about the half-moon?

Thanks!