- Joined

- Jul 19, 2019

- Messages

- 116

So another tool crossed off the 'To Do' list. Made a pair of machinist jacks, and wanted to post a few pics.

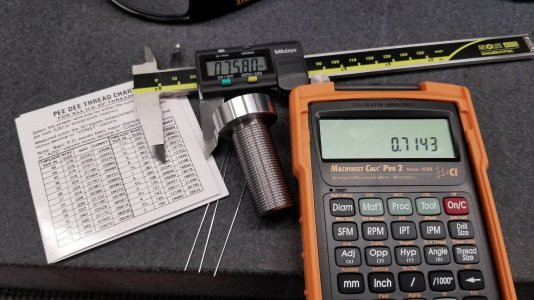

I started by turning down some 1.250" diameter Heat Treated 4140 and made the screw/head pieces first. That way I could measure my thread pitch and make sure it was within proper 2A specs. Then I drilled the top of the heads to accept some .375" diameter bushings with a .0005" press fit.

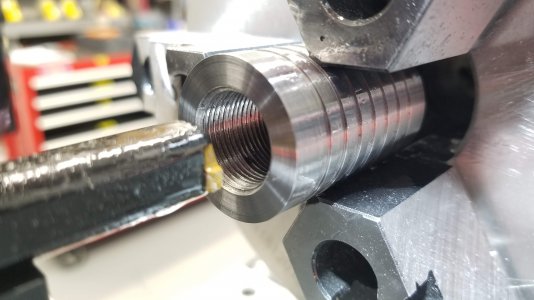

After that, I turned the jack bodies down to 1.200". With the screw threads already done and within specs, I was able to bore and thread the bodies 3/4-20 and get a very smooth and precise fit with zero slop. Then I turned some grooves along the outside of the bodies for aesthetics and better grip. These were parted off and faced to an OAL of 1.750".

The extensions are made 1.000" long with an upper shoulder for the body to sit on and a lower inner shoulder in case another extension needs to be added. The shoulders mated up very well.

Finally I made some caps and drilled and reamed the bottoms to .375". This allowed them to engage the head bushings and spin freely. I also put several varying-sized diameter grooves around the top and milled a .075" deep V-groove through the center of the cap. This allows smaller diameter stock to engage the groove and sit dead center when supported by the jack. I did not realize how handy and necessary these little jacks were, but I use them all the time now.

One more quick note...I also attached a magnified pic of some chips from the 4140. I spent more time trying to remove these little monsters from my shop broom than I did actually building the jacks. Now I know why LOL. Take a look at the teeth on those chips!

Thanks for reading guys and Happy Machining!! Be safe.

I started by turning down some 1.250" diameter Heat Treated 4140 and made the screw/head pieces first. That way I could measure my thread pitch and make sure it was within proper 2A specs. Then I drilled the top of the heads to accept some .375" diameter bushings with a .0005" press fit.

After that, I turned the jack bodies down to 1.200". With the screw threads already done and within specs, I was able to bore and thread the bodies 3/4-20 and get a very smooth and precise fit with zero slop. Then I turned some grooves along the outside of the bodies for aesthetics and better grip. These were parted off and faced to an OAL of 1.750".

The extensions are made 1.000" long with an upper shoulder for the body to sit on and a lower inner shoulder in case another extension needs to be added. The shoulders mated up very well.

Finally I made some caps and drilled and reamed the bottoms to .375". This allowed them to engage the head bushings and spin freely. I also put several varying-sized diameter grooves around the top and milled a .075" deep V-groove through the center of the cap. This allows smaller diameter stock to engage the groove and sit dead center when supported by the jack. I did not realize how handy and necessary these little jacks were, but I use them all the time now.

One more quick note...I also attached a magnified pic of some chips from the 4140. I spent more time trying to remove these little monsters from my shop broom than I did actually building the jacks. Now I know why LOL. Take a look at the teeth on those chips!

Thanks for reading guys and Happy Machining!! Be safe.

Attachments

-

20201221_164531.jpg367.4 KB · Views: 780

20201221_164531.jpg367.4 KB · Views: 780 -

20201221_192721.jpg325 KB · Views: 666

20201221_192721.jpg325 KB · Views: 666 -

20201221_213131.jpg392.4 KB · Views: 589

20201221_213131.jpg392.4 KB · Views: 589 -

20201221_213347.jpg676 KB · Views: 590

20201221_213347.jpg676 KB · Views: 590 -

20210117_155702.jpg1.4 MB · Views: 595

20210117_155702.jpg1.4 MB · Views: 595 -

20210117_143912.jpg602.6 KB · Views: 585

20210117_143912.jpg602.6 KB · Views: 585 -

20210117_185234.jpg348 KB · Views: 555

20210117_185234.jpg348 KB · Views: 555 -

20210117_192543.jpg272 KB · Views: 552

20210117_192543.jpg272 KB · Views: 552 -

20210101_180022.jpg611 KB · Views: 559

20210101_180022.jpg611 KB · Views: 559 -

20201229_134407.jpg307.9 KB · Views: 580

20201229_134407.jpg307.9 KB · Views: 580 -

20201228_185952.jpg346.6 KB · Views: 572

20201228_185952.jpg346.6 KB · Views: 572 -

20201228_191414.jpg540.8 KB · Views: 590

20201228_191414.jpg540.8 KB · Views: 590 -

20201231_080701.jpg52.9 KB · Views: 580

20201231_080701.jpg52.9 KB · Views: 580 -

20210124_193520.jpg429.2 KB · Views: 643

20210124_193520.jpg429.2 KB · Views: 643 -

20210124_193640.jpg503.7 KB · Views: 523,263

20210124_193640.jpg503.7 KB · Views: 523,263