- Joined

- Feb 2, 2013

- Messages

- 3,620

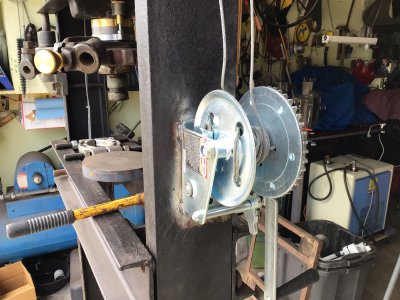

after seeing this masterpiece first hand, i can't see how the peanut gallery could really feel the gravity of this ultra-cool press.

i still have not, nor may i ever see, something so simple, so brute force utilitarian , and elegantly designed machine.

i would love to have a dire need to come and actually use it!!!!

i still have not, nor may i ever see, something so simple, so brute force utilitarian , and elegantly designed machine.

i would love to have a dire need to come and actually use it!!!!