-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Matts Precision Matthews 1236

- Thread starter zoom zoom

- Start date

- Joined

- Sep 24, 2014

- Messages

- 929

Being a new guy with no experience myself, all I can recommend is to take your time and explore the machine. Cleaning, adjusting and repairing minor issues allow you to become familiar with how the machine works. This forum is an awesome group of people who will answer any question you have, so don't be afraid to ask for help. Nobody will give you a hard time about "stupid" questions here, so do not be afraid to ask. Make sure that you work safely, being focused on doing something new can cause you to forget safety.

Congratulations and enjoy your new toy!

Congratulations and enjoy your new toy!

- Joined

- Jul 21, 2015

- Messages

- 566

Good luck with your new machine.

Congrats on the new lathe. It looks like the shipping company did a good job and didn't do any damage. If the safety shield bothers you, it's easy to remove but you'll have to bypass the limit switch inside. Have fun and take your time setting it up.

- Joined

- Sep 2, 2013

- Messages

- 378

Congratulations on your new lathe. I am very happy with mine. Good job on your write up and pictures/videos.

Rick

Rick

- Joined

- Aug 12, 2013

- Messages

- 858

That motor is way too hot. Unless you have been cutting for hours, that is unusual.

If its the cover of the junction box is getting hot, I would definitely open it up and check the connections on the wiring and make sure none of the terminal screws are loose. Take some pictures of the inside and post them.

Also, check to see if you can feel airflow from the fan that is mounted inside the end-bell on the motor (somebody who just bough a green mill from another company who will be unnamed, got a TEFC motor... without a fan....),

If its the cover of the junction box is getting hot, I would definitely open it up and check the connections on the wiring and make sure none of the terminal screws are loose. Take some pictures of the inside and post them.

Also, check to see if you can feel airflow from the fan that is mounted inside the end-bell on the motor (somebody who just bough a green mill from another company who will be unnamed, got a TEFC motor... without a fan....),

- Joined

- Jun 12, 2014

- Messages

- 4,806

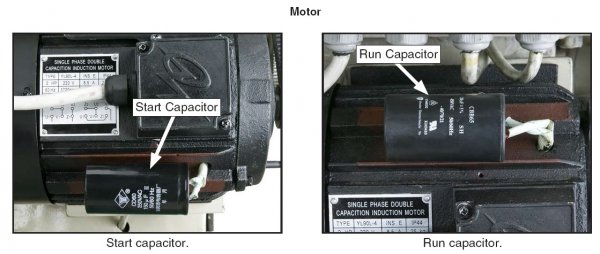

You may have a bad motor start/run capacitor or the motor start capacitor may not be disengaging. Based on similar machines, that looks to be the RUN 20 mfd capacitor that is getting very hot. I would see if it is just one capacitor or both, I would call QMT to see what they recommend before something goes south. If the breaker is tripping with starting the machine, they sometimes need to have a different trip curve that allow a longer time before tripping (C or D) and/or increased the breaker size from 20A to 25A to prevent nuisance tripping. You need to check electrical code to see what is acceptable. This spreadsheets provides recommended fusing/breaker for a 2Hp single phase 230V: http://www.schneider-electric.us/do...-and-online-tools/nemamotordatacalculator.xls

- Joined

- Nov 23, 2015

- Messages

- 71

Verify the motor wiring is configured properly for the 220v 1 phase ?