- Joined

- Nov 8, 2018

- Messages

- 35

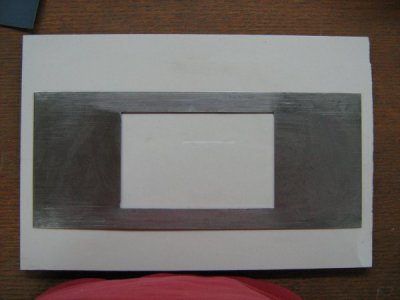

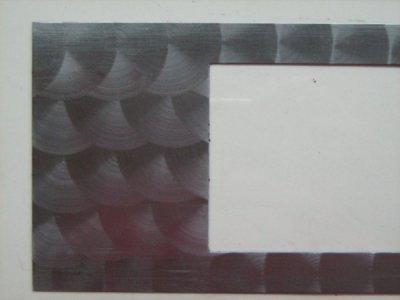

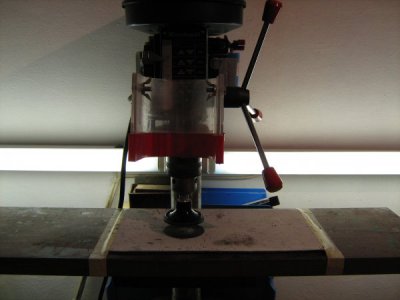

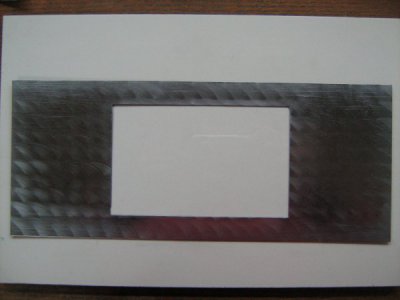

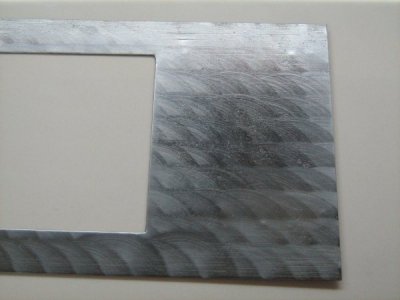

Hello. Recently I bought myself a birthday present. No need to mention that my wife was not so excited as me  This is my first serious machine. It is Mattson & Zetterlund VF600 (small) vertical milling machine. More about this machine can be found at: http://www.lathes.co.uk/mattsson&zetterlund/ . I hope I will restore it properly so it

This is my first serious machine. It is Mattson & Zetterlund VF600 (small) vertical milling machine. More about this machine can be found at: http://www.lathes.co.uk/mattsson&zetterlund/ . I hope I will restore it properly so it

will shine and be used again as intended. For sure, I will need advice and help down the path, so, I will post a pictures, comments and questions here. Wish me a luck

There is some pictures of machine as it was when arrived.

will shine and be used again as intended. For sure, I will need advice and help down the path, so, I will post a pictures, comments and questions here. Wish me a luck

There is some pictures of machine as it was when arrived.