- Joined

- Dec 20, 2012

- Messages

- 9,422

I've not seen or even heard of this model before - very nice.

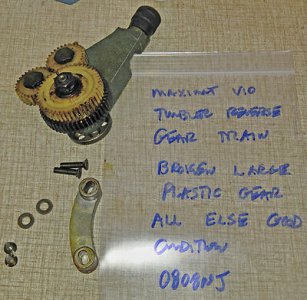

It appears from the Lathes uk site that the "bushing" you're looking for is probably a bolt that holds two gears that hang off the reverse tumbler, which is the part you are showing in post #4. Typically, Emco would use a one piece bolt with a hex shaped shoulder section in the middle. One side would thread into the casting and tighten into the head casting. The other end of the bolt would pass through the reverse tumbler lever and would be long enough to hold the two gears, washers and cap nut. This is just a guess, though. It might help to show some pics of the attachment point for the reverse tumbler.

The best thing would be to find the parts breakdown for your lathe. Emco typically shows every single part with enough detail to make a replacement.

Another option is to join the Emco Larger Lathes group on group.io and see if someone either has the manual/IPB or perhaps someone who owns one of these lathes.

It appears from the Lathes uk site that the "bushing" you're looking for is probably a bolt that holds two gears that hang off the reverse tumbler, which is the part you are showing in post #4. Typically, Emco would use a one piece bolt with a hex shaped shoulder section in the middle. One side would thread into the casting and tighten into the head casting. The other end of the bolt would pass through the reverse tumbler lever and would be long enough to hold the two gears, washers and cap nut. This is just a guess, though. It might help to show some pics of the attachment point for the reverse tumbler.

The best thing would be to find the parts breakdown for your lathe. Emco typically shows every single part with enough detail to make a replacement.

Another option is to join the Emco Larger Lathes group on group.io and see if someone either has the manual/IPB or perhaps someone who owns one of these lathes.