- Joined

- Nov 14, 2014

- Messages

- 851

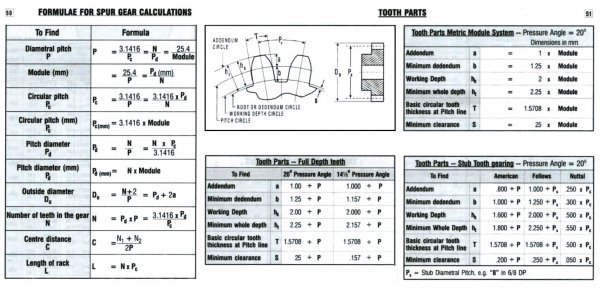

Ok, so all the tutorials say gear pitch is measured as teeth per inch (TPI). But so far, I’ve never read how to actually measure TPI.

Are the number of teeth per inch measured along a 1”chord, or around the outside diameter of the gear, or something else?

I would like to determine pitch of a gear we need to replace.

Thanks much,

Glenn

Are the number of teeth per inch measured along a 1”chord, or around the outside diameter of the gear, or something else?

I would like to determine pitch of a gear we need to replace.

Thanks much,

Glenn