- Joined

- Jun 19, 2018

- Messages

- 6

B

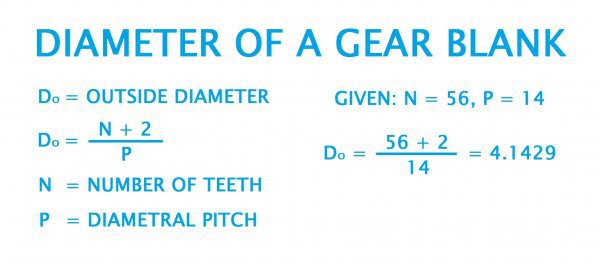

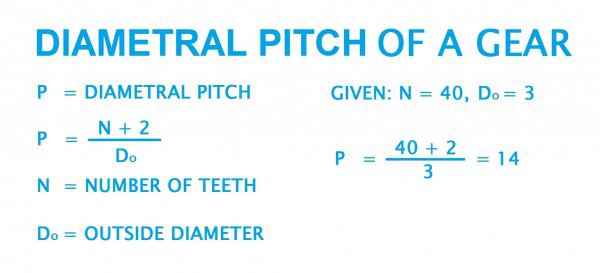

Wish this chart were larger, at my age I can no longer see small print.Yes, but written more correctly: (N + 2) then / by Dp. Or (N + 2) / Dp. Order of operation is the most common cause of people not liking math.

Try this chart for all your calculations.

View attachment 279727