I have not been able to find a source for bars of nickel. But, I have a source for 99% nickel small balls (like 1/4"). I would like to find someone that I can ship like 6 pounds of nickel balls too and who can melt them into a 1"x2"x6" (minus nothing, plus is fine) bar. What sort of job shop does something like this? Where do I find them? (After the nickel I have some other metals too I need reformed similarly). Thanks for any pointers. -Bill (previously posted this to a different forum, but got no responses, so have reposted here)

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Melting Nickel

- Thread starter Bill Kahn

- Start date

I retired from Vale the worlds 2nd largest nickel producer. I worked at the smelter, unfortunately they would only melt tons of nickel concentrate.

You requirement is a little on the small side

All joking aside, look for a local foundry or even build your own propane furnace. There are plenty of plans on the net, relatively cheap to construct.

You requirement is a little on the small side

All joking aside, look for a local foundry or even build your own propane furnace. There are plenty of plans on the net, relatively cheap to construct.

- Joined

- Jan 2, 2014

- Messages

- 8,850

look for a local foundry or even build your own propane furnace

aluminum is easy with my homemade propane burner, that's around 660 deg. C.

I tried and failed to melt copper. That should be 1080 deg.C.

I would think nickel at 1450 deg. C. would require an arc furnace......but I'm no expert.

-brino

melting points from here:

https://www.onlinemetals.com/en/melting-points

- Joined

- Feb 1, 2015

- Messages

- 9,568

You might have better luck buying nickel rounds and forging them to your rectangular shape. Nickel can be forged at around 1100ºC, slightly lower than carbon steels. A 1.75" round should work. Nickel rounds are available from Online Metals. Pretty pricey though.

- Joined

- May 4, 2019

- Messages

- 792

Buy a larger round and mill it to shape.

- Joined

- Feb 1, 2015

- Messages

- 9,568

A 2.25" round would be required to mill out a 1" x 2" profile. From Online Metals, a 2" round x 12" bar is $700.95. A 2.25 round, if available would more than likely add another $100. To mill the 1" x 2" profile, you would throw away half the material.Buy a larger round and mill it to shape.

- Joined

- Jul 10, 2013

- Messages

- 1,188

Bill, why do you need nickel? Would a cheaper metal work?

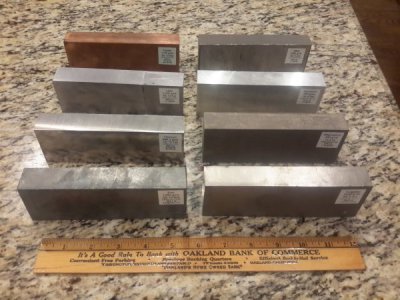

I have a small 1x2x6 metal collection. See snapshot.

It is really quite interesting how different these materials are. Copper has an incredible color. Tungsten makes lead feel light. Magnesium makes aluminum feel heavy. Titanium feels warm (5% of the thermal conductivity of copper). Bismuth has very sparkly crystal planes. I have managed to find inexpensive off-pieces--can't afford commercial prices.

There are many more safe elements that in principle are affordable.

What is a challenge is finding large enough pieces that I can mill down to 1x2x6. Zinc and Lead I was was able to melt myself. Tin and Bismuth I have the material, but need still to melt them (given they are more expensive materials I want to do so with less waste than the bread pan molds I have been using. But I'll get these done in a month or two.)

At times I come across an affordable source of the material, but it is in too small of a form factor. For some of the materials I can remelt them myself (though that is more of a challenge than one might think--I'll tell about my lead experience sometime--a lead brick is harder than you would think (as is true in all machining it seems)) And simply hitting copper with a propane torch simply oxidizes it in funny ways--does not melt it (would need to figure out how to limit the oxygen exposure I guess)

I came across a source of affordable nickel pellets. I just figured someone may have the furnace/mold equipment and be able to reform it for me not too expensively. At least, I want to find out what the cost might be.

From the outside all hobbies are pretty silly. So, I do know that working to acquire macro-sized and human experience-able chunks of elements is silly. It is a small way I connect to the real, tangible, physical world.

Elements I am am gently keeping my eyes open for now include:

Vanadium

Chromium

Manganese

Cobalt

Nickel

Zirconium

Niobium

Molybdenum

Antimony

Neodymium

Tantalum

Indium

If I can find a re-melter/molder the process becomes much easier--there are funny suppliers of scrap all over. But when a single piece is 1x2x6 it often has more than remnant value and so is no longer affordable to a hobbyist collector.

-Bill

It is really quite interesting how different these materials are. Copper has an incredible color. Tungsten makes lead feel light. Magnesium makes aluminum feel heavy. Titanium feels warm (5% of the thermal conductivity of copper). Bismuth has very sparkly crystal planes. I have managed to find inexpensive off-pieces--can't afford commercial prices.

There are many more safe elements that in principle are affordable.

What is a challenge is finding large enough pieces that I can mill down to 1x2x6. Zinc and Lead I was was able to melt myself. Tin and Bismuth I have the material, but need still to melt them (given they are more expensive materials I want to do so with less waste than the bread pan molds I have been using. But I'll get these done in a month or two.)

At times I come across an affordable source of the material, but it is in too small of a form factor. For some of the materials I can remelt them myself (though that is more of a challenge than one might think--I'll tell about my lead experience sometime--a lead brick is harder than you would think (as is true in all machining it seems)) And simply hitting copper with a propane torch simply oxidizes it in funny ways--does not melt it (would need to figure out how to limit the oxygen exposure I guess)

I came across a source of affordable nickel pellets. I just figured someone may have the furnace/mold equipment and be able to reform it for me not too expensively. At least, I want to find out what the cost might be.

From the outside all hobbies are pretty silly. So, I do know that working to acquire macro-sized and human experience-able chunks of elements is silly. It is a small way I connect to the real, tangible, physical world.

Elements I am am gently keeping my eyes open for now include:

Vanadium

Chromium

Manganese

Cobalt

Nickel

Zirconium

Niobium

Molybdenum

Antimony

Neodymium

Tantalum

Indium

If I can find a re-melter/molder the process becomes much easier--there are funny suppliers of scrap all over. But when a single piece is 1x2x6 it often has more than remnant value and so is no longer affordable to a hobbyist collector.

-Bill

Attachments

- Joined

- Jul 10, 2013

- Messages

- 1,188

Okay, I get it now. That is interesting what you are doing.I have a small 1x2x6 metal collection. See snapshot.

It is really quite interesting how different these materials are. Copper has an incredible color. Tungsten makes lead feel light. Magnesium makes aluminum feel heavy. Titanium feels warm (5% of the thermal conductivity of copper). Bismuth has very sparkly crystal planes. I have managed to find inexpensive off-pieces--can't afford commercial prices.

There are many more safe elements that in principle are affordable.

What is a challenge is finding large enough pieces that I can mill down to 1x2x6. Zinc and Lead I was was able to melt myself. Tin and Bismuth I have the material, but need still to melt them (given they are more expensive materials I want to do so with less waste than the bread pan molds I have been using. But I'll get these done in a month or two.)

At times I come across an affordable source of the material, but it is in too small of a form factor. For some of the materials I can remelt them myself (though that is more of a challenge than one might think--I'll tell about my lead experience sometime--a lead brick is harder than you would think (as is true in all machining it seems)) And simply hitting copper with a propane torch simply oxidizes it in funny ways--does not melt it (would need to figure out how to limit the oxygen exposure I guess)

I came across a source of affordable nickel pellets. I just figured someone may have the furnace/mold equipment and be able to reform it for me not too expensively. At least, I want to find out what the cost might be.

From the outside all hobbies are pretty silly. So, I do know that working to acquire macro-sized and human experience-able chunks of elements is silly. It is a small way I connect to the real, tangible, physical world.

Elements I am am gently keeping my eyes open for now include:

Vanadium

Chromium

Manganese

Cobalt

Nickel

Zirconium

Niobium

Molybdenum

Antimony

Neodymium

Tantalum

Indium

If I can find a re-melter/molder the process becomes much easier--there are funny suppliers of scrap all over. But when a single piece is 1x2x6 it often has more than remnant value and so is no longer affordable to a hobbyist collector.

-Bill