One of the hobbies is irrigation...yes we are odd.

It is more of the control of irrigation as it can have good tech.

Our home is on community water and the water pressure has always been a challenge.

In our former Motorola years we supported a Motorola product MIR5000 which was early generation system.

Many years later we have upgraded to current product, Irrinet PRO.

This allows us to control by volume using meters, vary the pressure using regulators and bypass valves and other creative things to make the most of limited resources.

The garden is all drip tape with flow rates 0.2 gallon per minute so we can get good control.

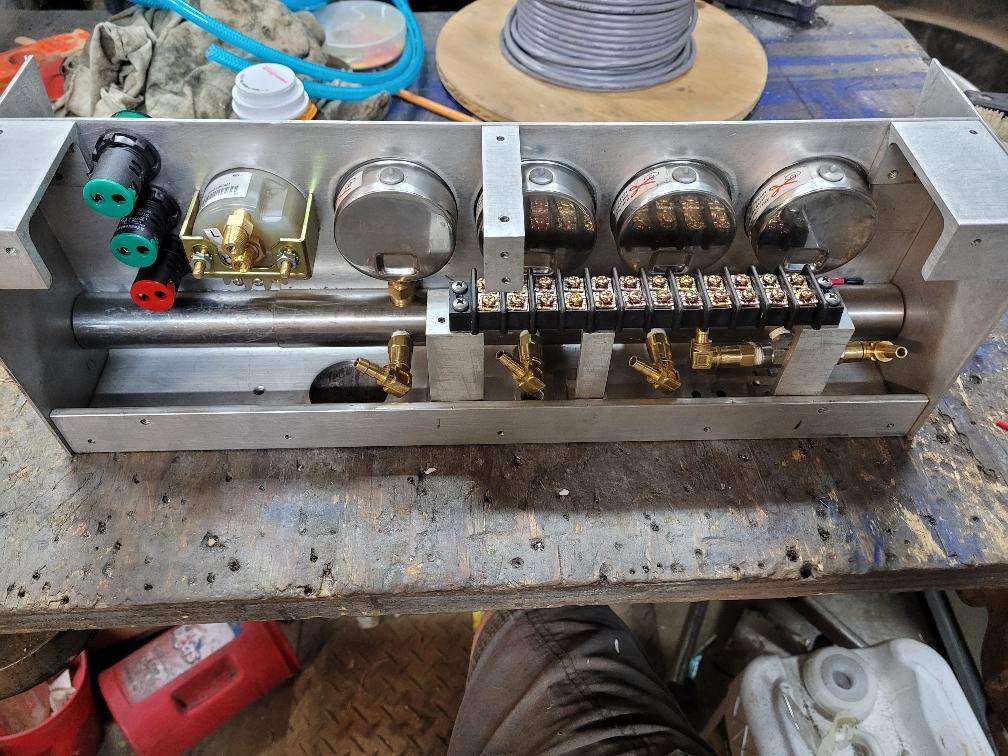

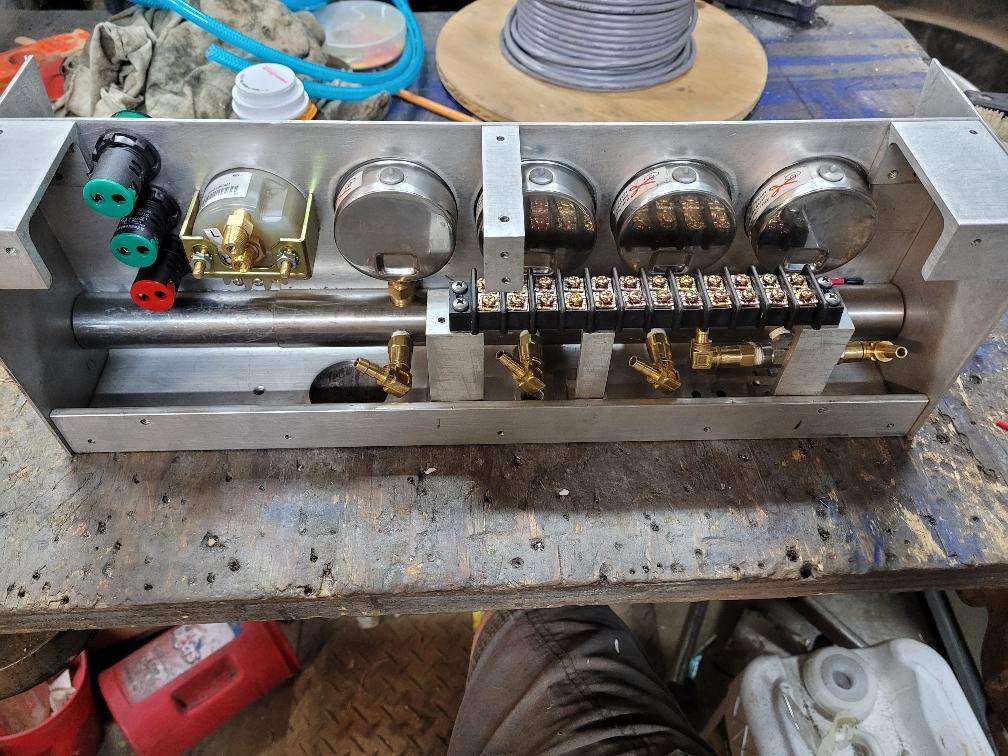

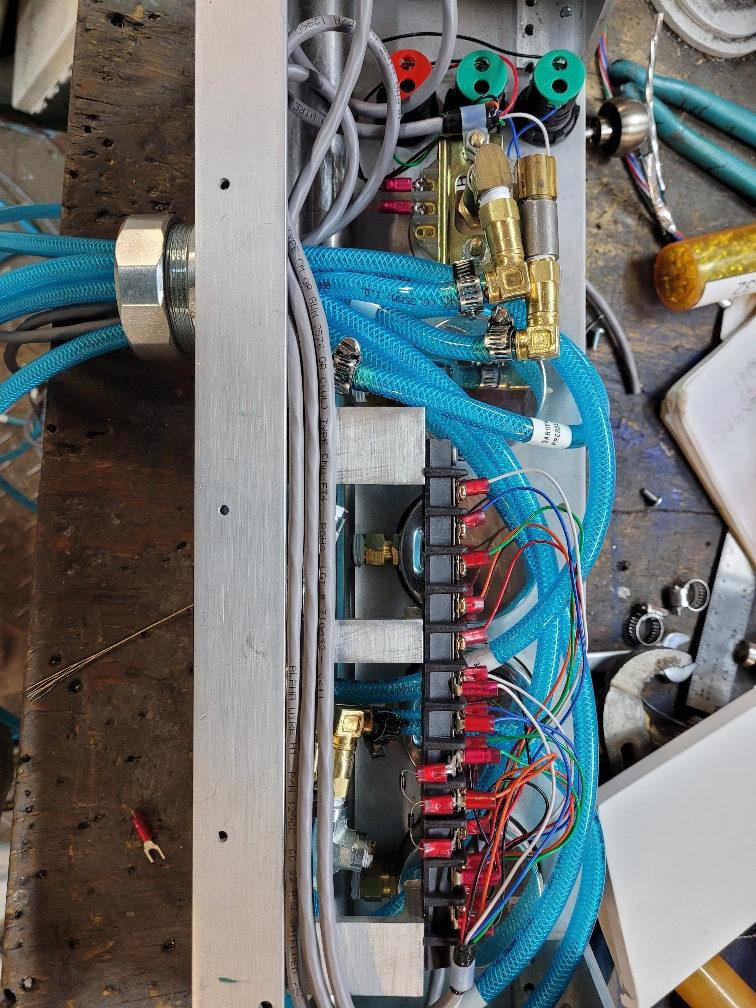

So we have a manifold with bunch of valves and the regulators.

We had pressure gages at different places to monitor pressure and it was sloppy.

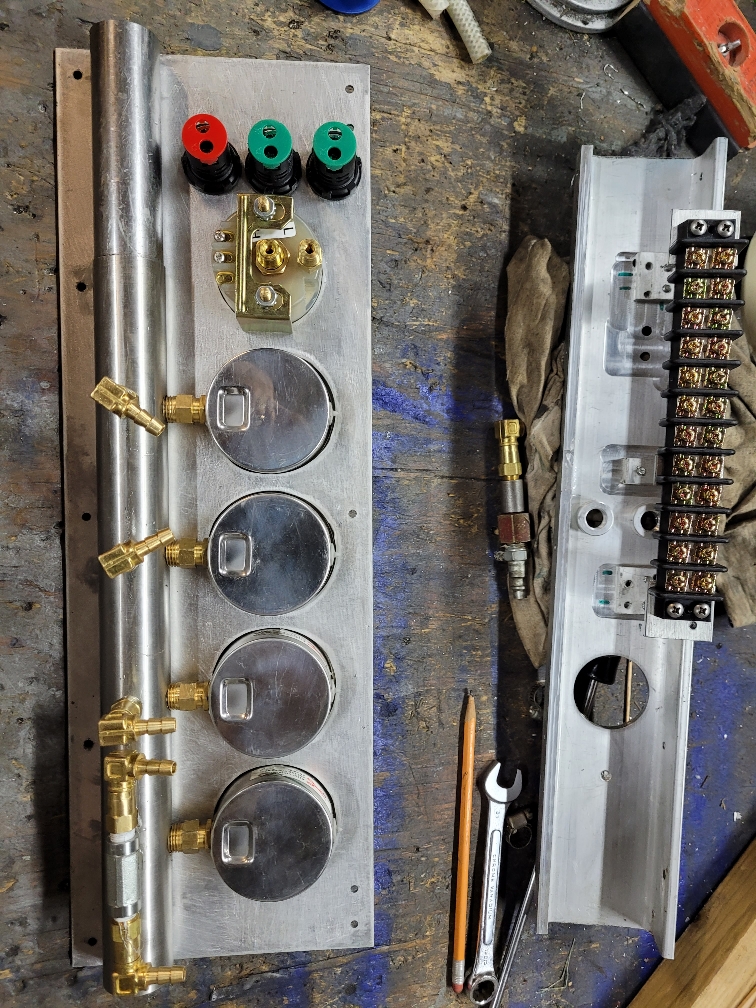

Picked up a handful of good units and decided to build a manifold to hold them since no brackets.

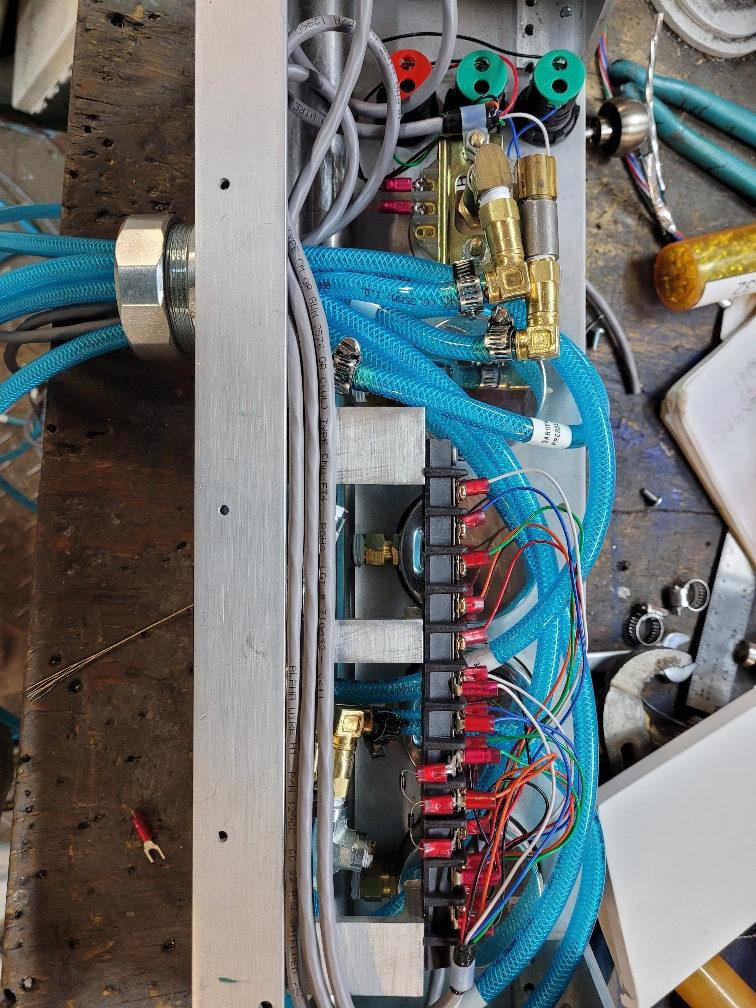

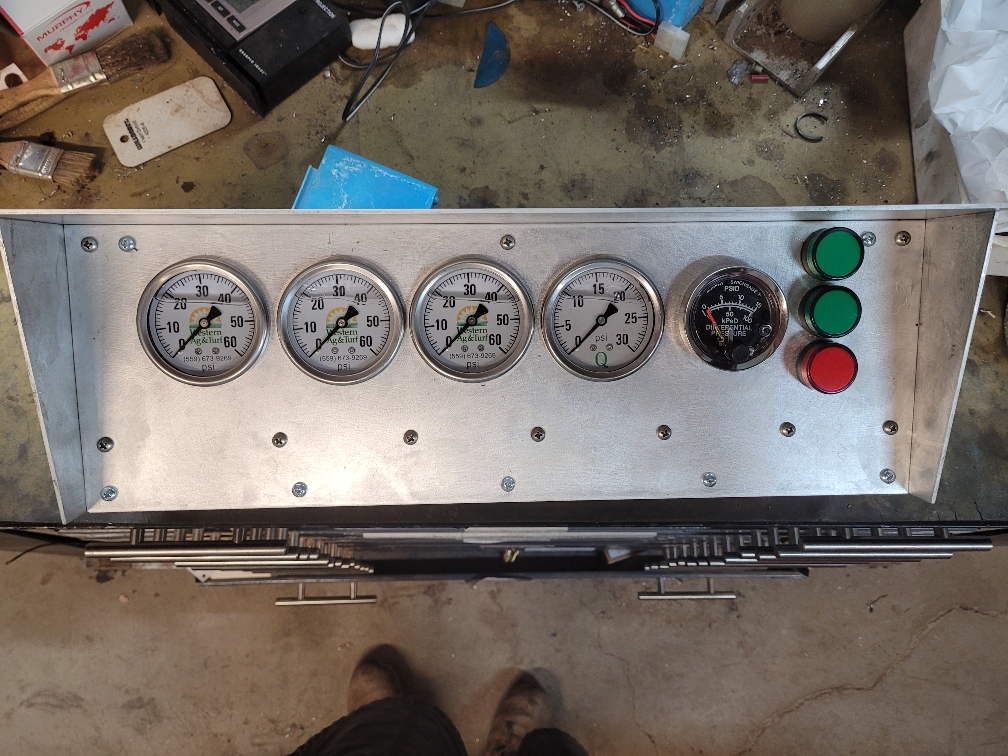

Just as we were ready to build the housing they had issues in the system and now the fine mesh filter clogs up often so we needed to add a differential switch, more work.

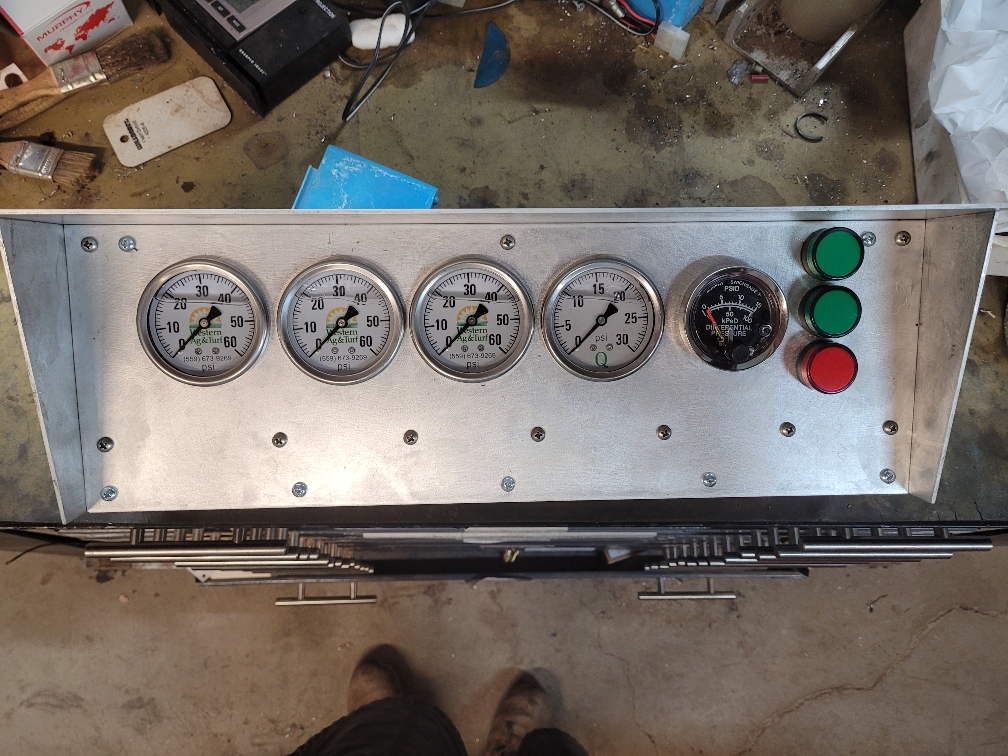

Since we needed to make a new cover we added some status and alarm LEDs.

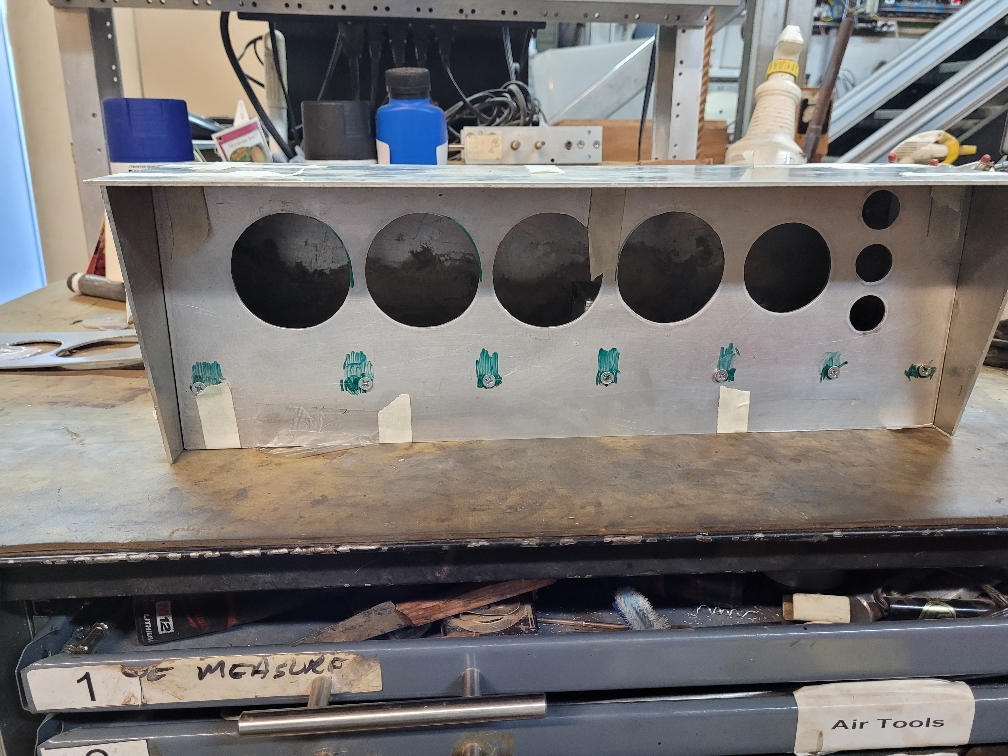

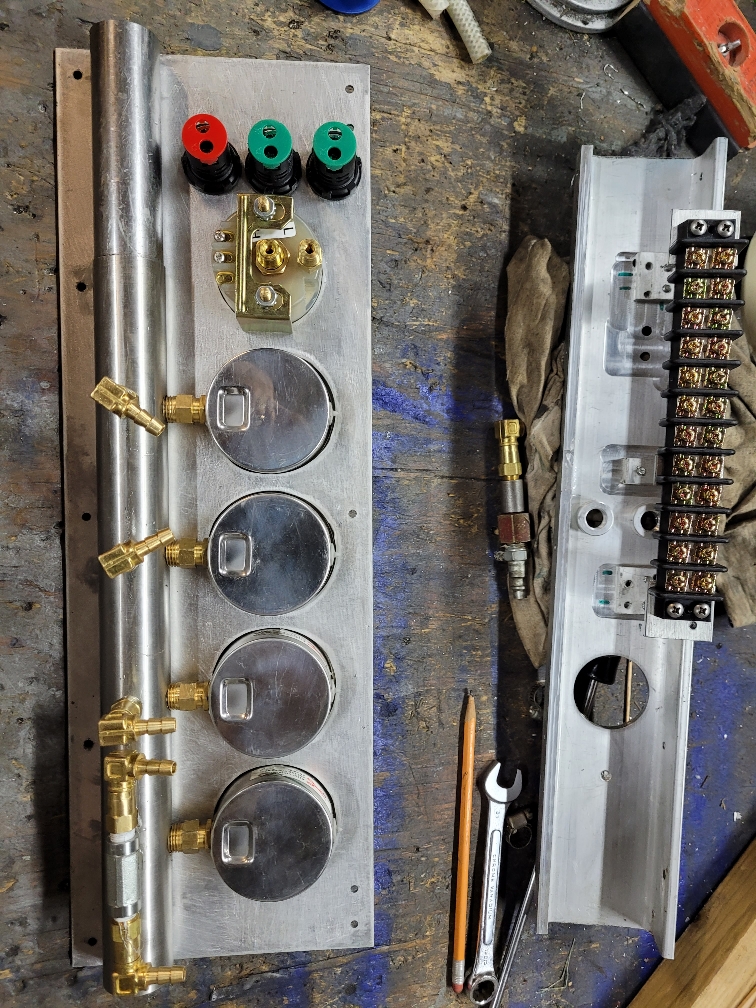

All of the aluminum was scrap.

The swivel brass fittings were from Restore, $0.25 ea.

The manifold is some stainless stuff from scrap yard, very difficult to tap pipe threads due to tapered threads.

The "frame" of the box is radio rack.

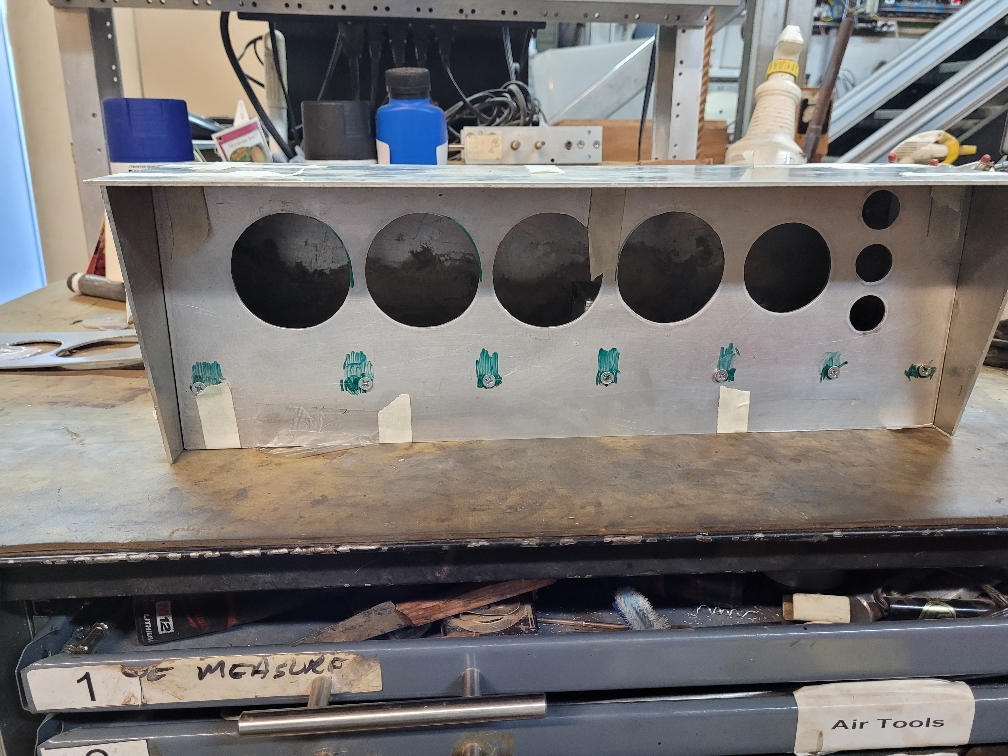

The face plate was difficult as the round holes first were punched, just happened to have a chassis punch the right size.

But the gages have the fitting on the bottom so it needs to go in at an angle.

It also has a fill plug on the top.

So careful measurement to get holes punched.

Then file them to allow the gages to pivot in.

Next screw in all of the gages through their holes then flip up the faceplate (filing as needed) to make it fit.

Once all together tear it apart and place the lettering and clear coat.

We then realize the sun at end of day will hit this and a cover is needed.

We like a double arm pivot like used on some cars as it allows the cover to pivot an move away.

Made brackets that used existing holes since it was built after the rest.

Needed latches to hold it closed.

Made some magnetic latches from cup hooks.

The 4-20ma sensors arrived and barely fit, this will allow the computer to record actual pressure.

Currently working on the wiring harness, using weather pac connectors so it just plugs in.

Sent from my SM-G781V using Tapatalk

It is more of the control of irrigation as it can have good tech.

Our home is on community water and the water pressure has always been a challenge.

In our former Motorola years we supported a Motorola product MIR5000 which was early generation system.

Many years later we have upgraded to current product, Irrinet PRO.

This allows us to control by volume using meters, vary the pressure using regulators and bypass valves and other creative things to make the most of limited resources.

The garden is all drip tape with flow rates 0.2 gallon per minute so we can get good control.

So we have a manifold with bunch of valves and the regulators.

We had pressure gages at different places to monitor pressure and it was sloppy.

Picked up a handful of good units and decided to build a manifold to hold them since no brackets.

Just as we were ready to build the housing they had issues in the system and now the fine mesh filter clogs up often so we needed to add a differential switch, more work.

Since we needed to make a new cover we added some status and alarm LEDs.

All of the aluminum was scrap.

The swivel brass fittings were from Restore, $0.25 ea.

The manifold is some stainless stuff from scrap yard, very difficult to tap pipe threads due to tapered threads.

The "frame" of the box is radio rack.

The face plate was difficult as the round holes first were punched, just happened to have a chassis punch the right size.

But the gages have the fitting on the bottom so it needs to go in at an angle.

It also has a fill plug on the top.

So careful measurement to get holes punched.

Then file them to allow the gages to pivot in.

Next screw in all of the gages through their holes then flip up the faceplate (filing as needed) to make it fit.

Once all together tear it apart and place the lettering and clear coat.

We then realize the sun at end of day will hit this and a cover is needed.

We like a double arm pivot like used on some cars as it allows the cover to pivot an move away.

Made brackets that used existing holes since it was built after the rest.

Needed latches to hold it closed.

Made some magnetic latches from cup hooks.

The 4-20ma sensors arrived and barely fit, this will allow the computer to record actual pressure.

Currently working on the wiring harness, using weather pac connectors so it just plugs in.

Sent from my SM-G781V using Tapatalk