- Joined

- Feb 17, 2013

- Messages

- 4,406

I have a wonderful stand for inch taps and drills, that I bought (fully populated with quality drills & taps) from an industrial supplier in Oregon a bunch of years ago.

Wanting something similar for metrics, I bought this one about 2 years ago.

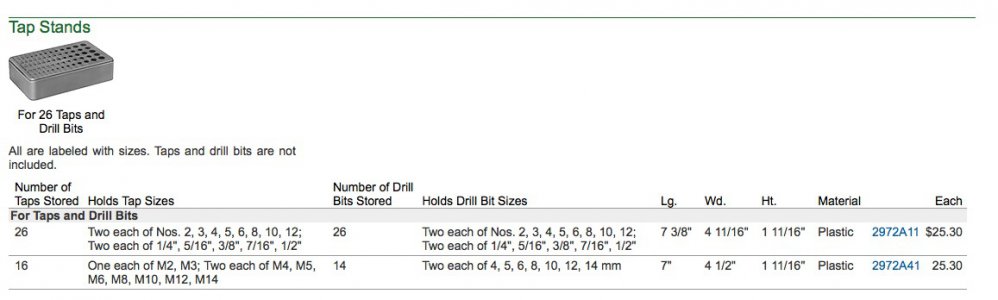

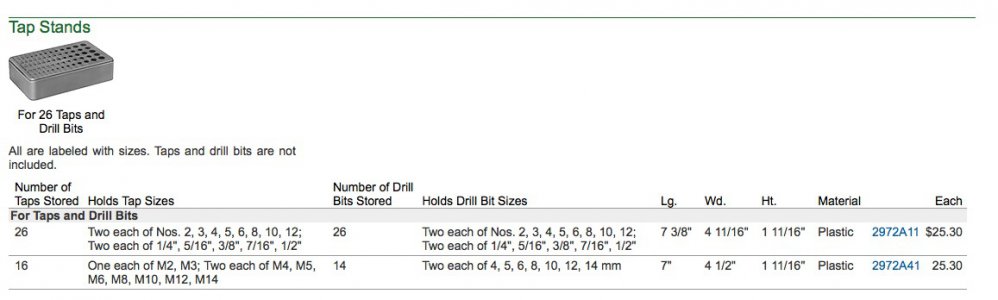

FOOEY! It's loaded with errors - wrong or very non-standard pitches, improperly sized molded holes, etc. Been searching for a better one for quite a while, and finally decided to take a chance on p/n 2972A41 from McMaster-Carr. It sounded like it differed somewhat from the "yellow peril," so maybe a new mold. And not too expensive - just over $25.

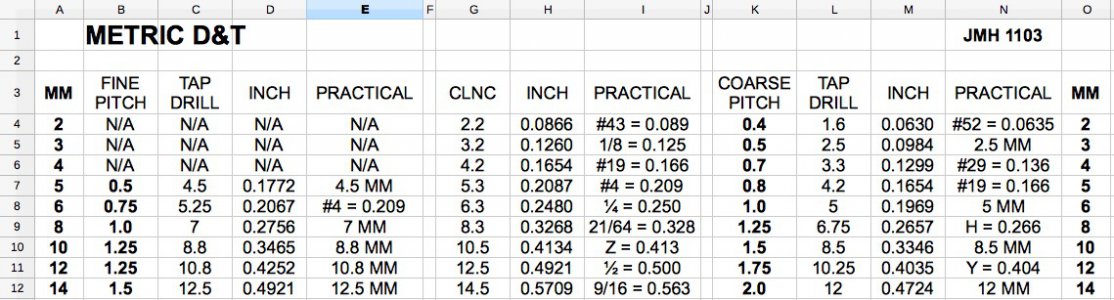

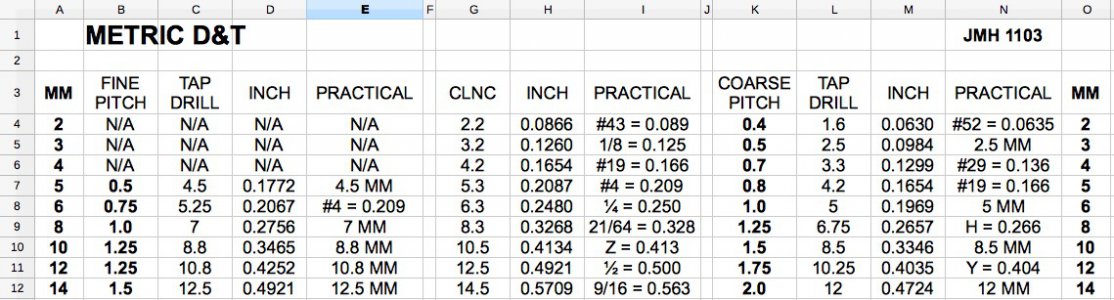

It turns out that there are still some errors on this one (like overly large clearance hole specifications and a very odd thread pitch or two), but a lot fewer than on the other. I decided it was worth correcting. Started by sanding the top smooth (wet sandpaper on the surface plate) to get rid of the slightly raised numbers. Then I gave it a couple coats of white primer. While waiting for the paint to dry I worked up a spreadsheet to calcualte the "best possible/practical" drill sizes for the various thread pitches. In a surprising number of cases, a fractional/letter/number drill bit was more suitable than the nearest available metric.

After trying and rejecting Sharpies (they'd run when covered with clear coat) I used one of my "vintage" Rapidograph (India ink) pens to write the tap and drill sizes on the face of the stand, then covered with two thin coats of clear. Ordered some missing sizes from McMaster and Amazon, and I'm now in business. The die pockets are a split-in-half length of PVC pipe.

Note the "nest" for a thread pitch gauge:

Wanting something similar for metrics, I bought this one about 2 years ago.

FOOEY! It's loaded with errors - wrong or very non-standard pitches, improperly sized molded holes, etc. Been searching for a better one for quite a while, and finally decided to take a chance on p/n 2972A41 from McMaster-Carr. It sounded like it differed somewhat from the "yellow peril," so maybe a new mold. And not too expensive - just over $25.

It turns out that there are still some errors on this one (like overly large clearance hole specifications and a very odd thread pitch or two), but a lot fewer than on the other. I decided it was worth correcting. Started by sanding the top smooth (wet sandpaper on the surface plate) to get rid of the slightly raised numbers. Then I gave it a couple coats of white primer. While waiting for the paint to dry I worked up a spreadsheet to calcualte the "best possible/practical" drill sizes for the various thread pitches. In a surprising number of cases, a fractional/letter/number drill bit was more suitable than the nearest available metric.

After trying and rejecting Sharpies (they'd run when covered with clear coat) I used one of my "vintage" Rapidograph (India ink) pens to write the tap and drill sizes on the face of the stand, then covered with two thin coats of clear. Ordered some missing sizes from McMaster and Amazon, and I'm now in business. The die pockets are a split-in-half length of PVC pipe.

Note the "nest" for a thread pitch gauge: