Hi all, sorry the only time I post is when I need help, I have an old clausing 100, built sometime during the war according to the war order sticker, with the quick change gear box.

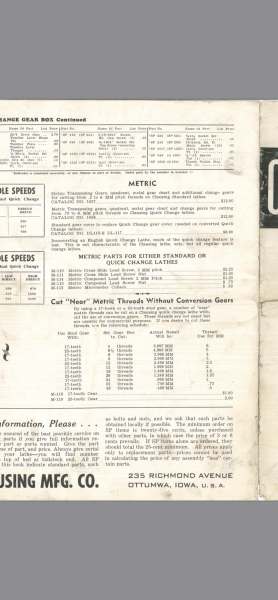

My question is while I was searching the best way to turn a metric thread, an old manual for this lathe popped up, and said it can cut “near perfect metric threads” with just a 17 or 23 tooth gear on the stud, unfortunately I cant find any other info about this, has anyone turned a metric thread this way? If so and it worked, I’ll be making a couple of new small gears, which will be much easier than making 100 and 127 tooth gears . Here’s a photo from the manual that I got from vintagemachinery.com

My question is while I was searching the best way to turn a metric thread, an old manual for this lathe popped up, and said it can cut “near perfect metric threads” with just a 17 or 23 tooth gear on the stud, unfortunately I cant find any other info about this, has anyone turned a metric thread this way? If so and it worked, I’ll be making a couple of new small gears, which will be much easier than making 100 and 127 tooth gears . Here’s a photo from the manual that I got from vintagemachinery.com