I acquired an older set of outside mechanical micrometers made by the (now defunct) New Britain Tool Company (a brand under the Litton Tool Company), once sold through NAPA, probably in the 1970's. They appear to be in decent overall shape and still in the original storage box. There is no documentation other than the "New Britain" label on the outside of the box and on the tools themselves it says "New Britain Made in USA", but no part numbers, etc..

I'd like to adjust the calibration setting on a couple of them, but these are not made like most micrometers that I'm familiar with. They have no hole for an adjustment wrench (and no wrench), and the thimble body is a one piece type (no two-piece friction adjustment). So how do you adjust them? I searched but wasn't able to find any information about these specifically online; apparently they weren't very popular because I did not see any mention of them anywhere.

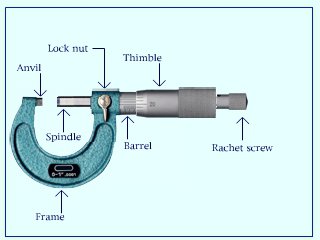

Here are some pics, anyone know how to adjust this type?

I'd like to adjust the calibration setting on a couple of them, but these are not made like most micrometers that I'm familiar with. They have no hole for an adjustment wrench (and no wrench), and the thimble body is a one piece type (no two-piece friction adjustment). So how do you adjust them? I searched but wasn't able to find any information about these specifically online; apparently they weren't very popular because I did not see any mention of them anywhere.

Here are some pics, anyone know how to adjust this type?