- Joined

- Nov 6, 2021

- Messages

- 60

I received a nice Kitchen Knife kit for Christmas where I need to add a handle (Knife Scale, I guess they're called). The kit includes some press together rivets to help hold the sides in place (the sides are also epoxied in place so the rivets may be entirely decorative). However, I'd like to use mosaic pins instead of the rivets. The pins are 6mm diameter, but the holes in the tang are oval, rounded slots ~5.7mmx3.7mm, so the holes need to be opened up.

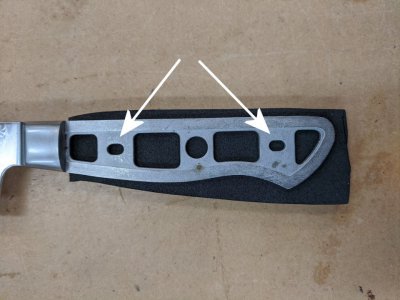

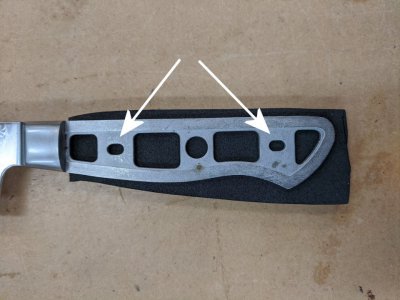

Here's what the tang looks like, the two holes are shown with arrows:

I've have read that the tang is very hard metal and tough to drill. What is the recommendation for opening up these two holes to 6mm round? I have a LMS3990 Mini Mill that I can use to Drill, Mill, or ream these holes precisely in the center of each oval, but I'm not sure what the best method would be. It seems as if a twist drill would catch in the oval opening...

Here's what the tang looks like, the two holes are shown with arrows:

I've have read that the tang is very hard metal and tough to drill. What is the recommendation for opening up these two holes to 6mm round? I have a LMS3990 Mini Mill that I can use to Drill, Mill, or ream these holes precisely in the center of each oval, but I'm not sure what the best method would be. It seems as if a twist drill would catch in the oval opening...